The Best Custom Boat Lines, Custom Colored Ropes, & Special Assemblies made to Your Specifications

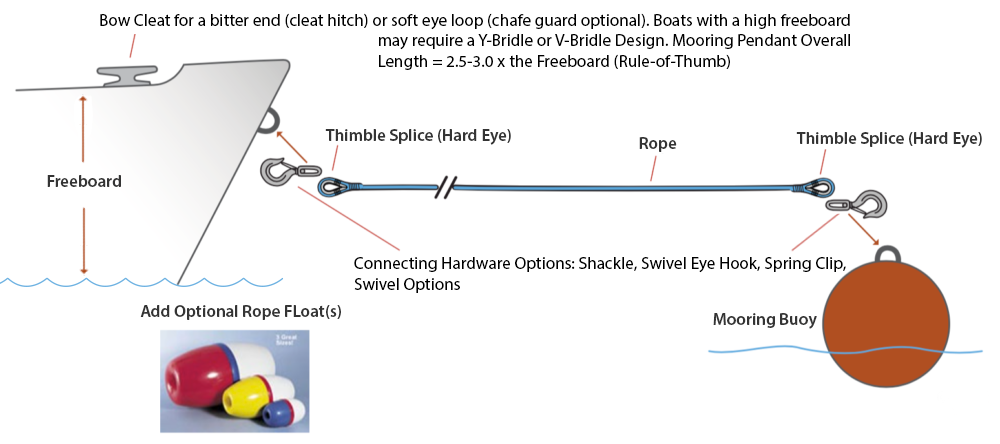

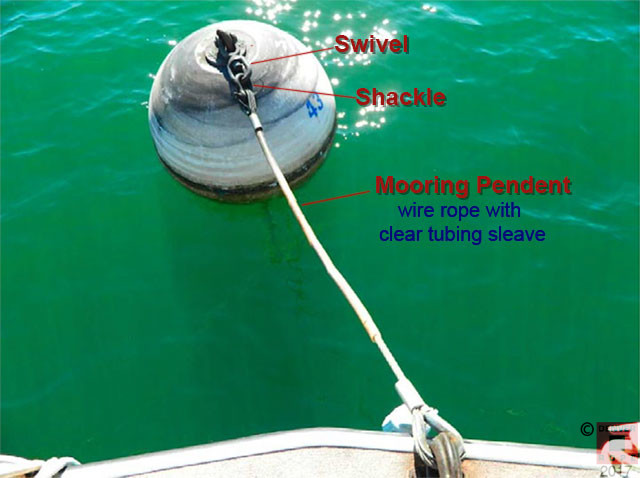

Mooring Pendant (type of mooring line) is a relatively short length of line used to connect a vessel to a mooring buoy (or mooring) usually via the boat’s bow eye or bow cleats. The boat can free wheel about the mooring depending on the wind direction.

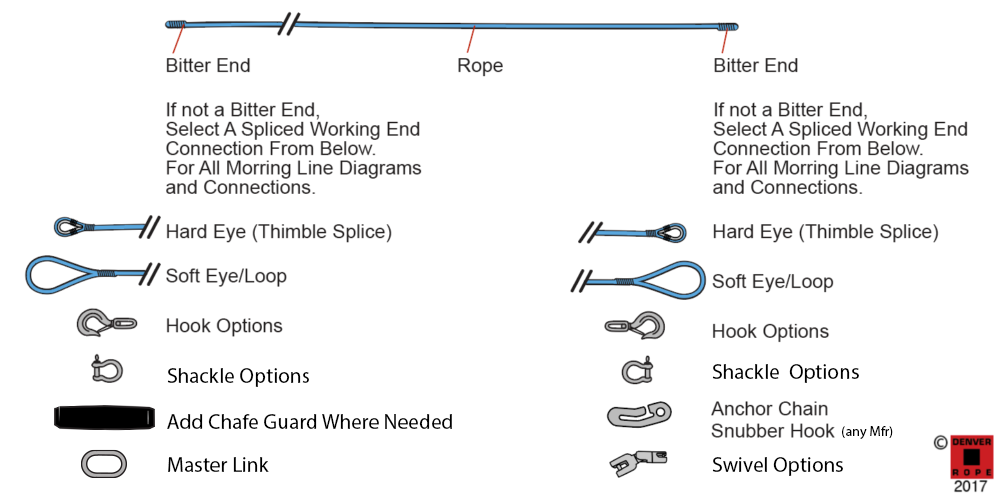

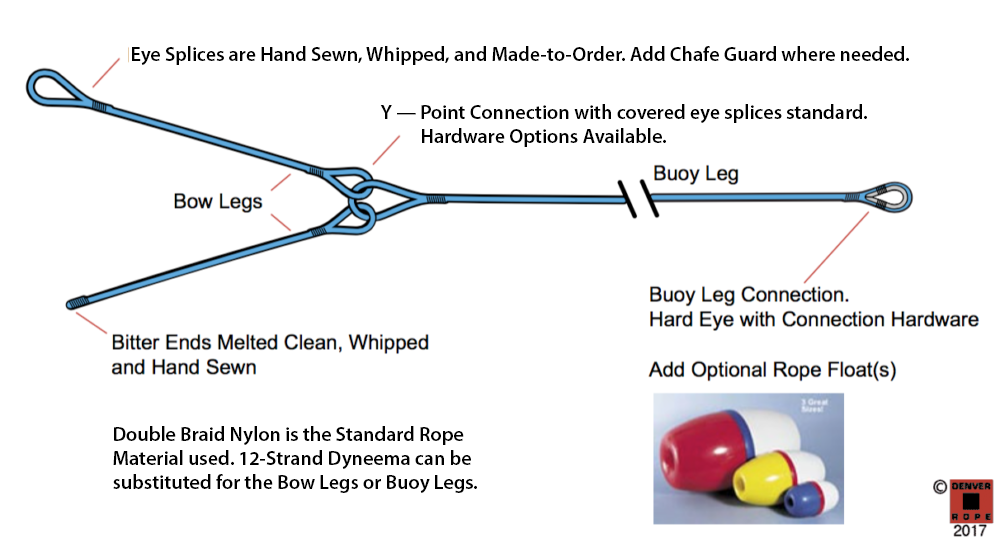

Buoy Field Mooring - When a boat is moored in a buoy field, a custom mooring line can be utilized i.e. a Mooring Pendant, which have characteristics of both dock lines and anchor lines and the associated hardware connections. A typical line will have a dock line eye splice (covered eye) for connecting to the boat’s cleat or a hard eye for connecting to the boat’s trailer bow eye via hardware. On the other end, a hard eye with a stainless steel swivel hook, spring clip, anchor swivel, and or shackle for making fast to the buoy connection. The mooring line might well be fitted with a buoy or rope float(s). Mooring Pendant Bridle assemblies have the shape of a V or Y depending on the Owner’s preference.

Thimble Eye Splice — Mooring Pendants like anchor lines are provided with a thimble eye splice on one end (even both ends), which provides rope chafe protection for the connection to a shackle, swivel eye hook, anchor swivel, or spring clip. The hook or clip connects the thimble eye of the mooring line directly to the bow eye of the boat being moored and or the mooring buoy. The mooring line might well be fitted with a rope float(s). Simply select the required splices and hardware for each end of the mooring pendant as required for your application.

Permanent or Shackled Connections — The connection between the mooring pendant and the swivel eye hook or shackle can be a permanent spliced connection (the hook is connected directly to the thimble) or a temporary connection (the hook is connected to the thimble via a shackle).

Covered Eye Splices — To protect an eye splice from chafing on a cleat, the eye splice can be providing with chafe guard tubing. The same chafe guard tubing can be also installed below the eye down the line to protect the rope from chafing against hawser holes, etc. Several Chafe Guard Options are Available.

Hardware — As the working load limit of the Mooring Pendant increases, the type of hardware that may be used becomes more critical (HD Thimbles, Quick Release Snap Shackles, and Trigger Release Shackles). We have both galvanized and stainless steel hardware.

Freeboard — Is the distance from the water line to the deck. For boats with a low freeboard, it is usually possible to have access to the trailer bow eye in order to connect a single leg mooring pendant. Motor Yachts and Sailboats with a high freeboard and no ease-of-access to trailer bow eye and or they do not have one, it is then necessary to use the bow cleats in order to connect the mooring bridle legs to the mooring system.

Overall Length — The rule-of-thumb for the OAL of the mooring pendant assembly = 2.5x - 3.0x the freeboard minimum unless otherwise directed by the mooring field manager or other AHJ. For Y-Bridle applications, the length of the bow bridle legs is 2x the distance between the bow cleats minimum in order to keep the inside angle formed by the bridle legs at the Y-Point very acute.

Rope Fiber and Construction — Our most popular choice for mooring line applications is Double Braid Nylon Construction (DBN) selected for its shock absorption properties, which we manufacture ourselves on our own rope machines. All our mooring lines are spliced-to-order. The minimum length of rope we splice for DBN is 6ft. If the line is shorter, we then switch to 3-Strand Nylon because the spliced length of the bury is much shorter.

12-Strand Dyneema — Selected for its high strength, high abrasion and wear resistance, but with no stretch and higher cost. Dyneema rope is often used to substitute a portion of a bridle assembly that would otherwise be made from DBN rope. For example the bridle legs or buoy leg will see a reduction of 3/8” in rope diameter as compared to same strength of DBN rope can be realized. We do recommend that some portion of the mooring bridle assembly be constructed from DBN rope in order to provide the desired shock absorption properties.

Rope Strength — The Mooring Line Strength (WLL or MBS) can be made in consideration of the Boat’s Dock Line Size, the Anchor Line / Anchor Chain Size, and or the Mooring Characteristics. We’ll then size the mooring line assembly to match and or exceed these components.

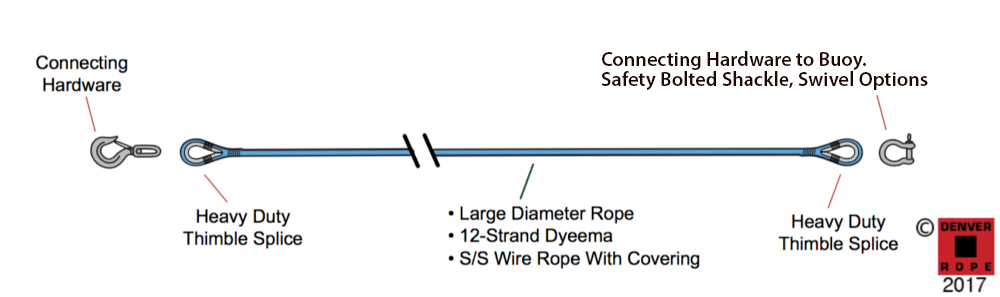

Single Leg Mooring Pendant — As the name implies, a single piece of line is assembled with the required splices and or hardware on each end of the line (bow connection and buoy connection). The mooring pendant might well be fitted with a buoy or rope float(s).

Double Leg Mooring Pendant — As the name implies, two independent single pieces of line are assembled with the required splices and or hardware on each end of the line (bow connection and buoy connection). The mooring pendant might well be fitted with a buoy or rope float(s). Many owners might well specify a Primary Mooring Pendant with all the preferred features and options, but also a smaller diameter and longer length Back-Up or Secondary Mooring Line with only the basic features needed. Another option is to use two full sized independent mooring pendants instead of a spliced bridle arrangement.

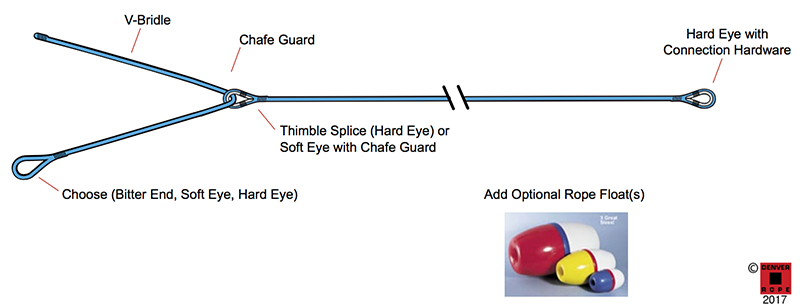

V-Shaped Mooring Bridle — Usually for boats with a high freeboard, one piece of line (V-Leg) with a dock line eye splice (soft covered eye) on one end of the line and the other end of the line is bitter. Each for connecting to the boat’s port and starboard bow cleats. Chafe guard can be applied to the middle of the line. A second piece of line (Buoy-Leg) is passed through the first in the middle via a slippery thimble eye splice or soft eye splice. The other end of this line is connected to the mooring buoy via a hard eye splice and hardware. The buoy leg might well be fitted with a buoy or rope float(s). With a long V-Leg, the amount of line paid out can be adjusted at the bitter end. However, the buoy leg can move unpredictable along the V-Leg with severe weather and wave action. This arrangement is not often used for mooring pendants, but more often utilized for towing applications.

Y-Shaped Mooring Bridle — Usually for boats with a high freeboard, two pieces line each with a dock line eye splice (soft covered eye) one for connecting to the boat’s port bow cleat and the other line for connecting to the starboard bow cleats. These two lines (bow bridle legs) are joined to a third piece of line (buoy leg) via soft covered eye splices. At the Y-point, hard eye splices and hardware can be substituted for the soft covered eye splices. The other end of the buoy leg is connected to the mooring buoy via a hard eye splice and hardware. The mooring bridle legs might well be fitted with a buoy or rope float(s). This arrangement is our most popular bridle arrangement, both for mooring and towing purposes.

House Boat Mooring Pendant — The same design concept as the single leg mooring pendant, but applied to a large boat like a houseboat. Larger diameter mooring rope and heavy duty hardware is required for this application. Wire rope can be substituted for fiber rope, but stainless steel wire rope and hardware is recommended. High Performance 12-Strand Dyneema rope is a good choice for this application. The mooring pendant might well be fitted with a buoy or rope float(s).

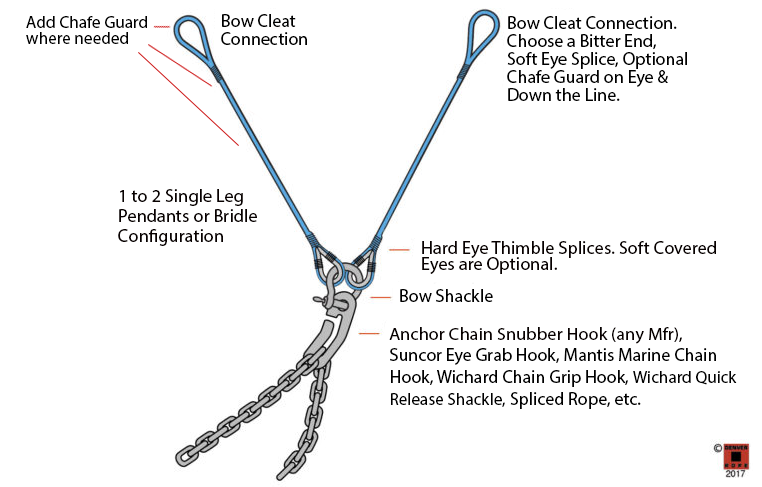

Anchor Chain Bridles, Anchor Chain Snubber Pendants, and Mooring Bridles — Have the same design concepts as the mooring pendants and mooring bridles described above; however, they are used to provide a degree of shock absorption for a boat’s anchor chain. One end of the line connects to the bow cleat(s), while the other end connects to the chain via a hard eye thimble splice and hardware (shackle, hook, rope, etc.).

CONCERNING CUSTOM MADE-TO-ORDER MOORING LINES — Please consider that many of our mooring pendant requests are for double braid nylon construction; however, we can generally utilize any of the rope materials described in Chapter 2 “Rope Selection Guide” and Chapter 5 “Bulk Rope”. Note there are additional diameters and rope lengths available upon request. All our mooring lines are custom made-to-order so we do not have part numbers for custom assemblies. Do not see what you are looking for, just ask.

Rope Strength Guide

For a Table of Rope Diameters and Tensile Strengths for different Rope Types, please continue to our ROPE STRENGTH GUIDE webpage. [Continue to ROPE STRENGTH GUIDE webpage]

V-Shaped Mooring Bridle Diagram

Mooring Pendant Diagram

Houseboat Mooring Pendant Diagram

Y-Shaped Mooring Bridle Diagram

Anchor Chain Snubber Diagram

Use any combination of the previous diagrams and hardware to fit your application. Anchor Chain Snubber Bridles and Anchor Chain Snubber Pendants are custom made-to-order and can be Single Leg or Bridle Configuration using Soft Eye Splice or Hard Eye Hardware Connections. We can apply your favorite Anchor Chain Snubber Hook (any Mfr).

Custom, Made-to-Order: Mooring Bridles, Mooring Pendants, Anchor Chain Snubber Bridles, & Anchor Snubber Pendants

| Mooring Bridle / Mooring Pendant Strength Guide | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NYLON DOUBLE BRAID (DBN) Single Leg Pendant |

DBN Y-Bridle Configuration with each bridle leg at least 2x the boat's beam (min) |

12-STRAND DYNEEMA® Single Leg Pendant or Buoy Mooring Leg to Join the Bridle Legs |

S/S Bow Shackle | S/S Safety Bolted Shackle | GALV Safety Bolted Shackle | Quick Release Snap Shackle | Trigger Release LB Shackle | Wire Rope or HD Thimble | |||||||

| Diameter | Tensile | WLL 5:1 | Tensile | WLL 5:1 | Diameter | Tensile | WLL 5:1 | ||||||||

| inches | mm | pounds | pounds | pounds | pounds | inches | mm | pounds | pounds | ||||||

| 1/2" | 13 | 7,300 | 1,460 | 12,167 | 2,433 | 5/16" | 8 | 12,300 | 2,460 | 1/2" | 1/2" | 7/16" | W2776 | T12 | Reqd |

| 5/8" | 16 | 14,600 | 2,920 | 24,333 | 4,867 | 3/8" | 10 | 17,600 | 3,520 | 5/8" | 5/8" | 1/2" | W2776 | T20 | Reqd |

| 3/4" | 19 | 19,000 | 3,800 | 31,667 | 6,333 | 1/2" | 13 | 30,600 | 6,120 | 1-0" | 3/4" | 5/8" | W2777 | T20 | Reqd |

| 7/8" | 22 | 28,100 | 5,620 | 46,833 | 9,367 | 5/8" | 196 | 47,500 | 9,500 | 1-1/4" | 7/8" | 3/4" | W2778 | T30 | Reqd |

| 1-0" | 25 | 33,200 | 6,640 | 55,333 | 11,067 | 3/4" | 19 | 58,000 | 11,600 | 1-0" | 7/8" | W2778 | T30 | Reqd | |

| 1-1/4" | 32 | 52,000 | 10,400 | 86,667 | 17,333 | 7/8" | 22 | 81,700 | 16,340 | 1-1/4" | 1-0" | T30 T40 | Reqd | ||

| 1-1/2" | 38 | 74,000 | 14,800 | 123,333 | 24,667 | 1-0" | 25 | 98,100 | 19,620 | 1-1/4" | 1-1/8" | T40 | Reqd | ||

| 1-5/8" | 41 | 92,100 | 18,420 | 153,500 | 30,700 | 1-1/4" | 32 | 149,000 | 29,800 | 1-1/4" | T50 | Reqd | |||

| 1-3/4" | 45 | 109,500 | 21,900 | 182,500 | 36,500 | 1-1/2" | 38 | 205,000 | 41,000 | 1-1/2" | T50 | Reqd | |||

| 2-0" | 51 | 129,700 | 25,940 | 216,167 | 43,233 | 1-1/2" | 38 | 205,000 | 41,000 | 1-1/2" | Reqd | ||||

| 2-1/4" | 57 | 179,400 | 35,880 | 299,000 | 59,800 | 1-3/4" | 45 | 302,000 | 60,400 | 1-3/4" | Reqd | ||||

| 2-1/2" | 64 | 196,000 | 39,200 | 326,667 | 65,333 | 2-0" | 51 | 343,000 | 68,600 | 2-0" | Reqd | ||||

| 2-5/8" | 67 | 221,000 | 44,200 | 368,333 | 73,667 | 2-0" | 51 | 343,000 | 68,600 | 2-0" | Reqd | ||||

| 2-3/4" | 70 | 237,000 | 47,400 | 395,000 | 79,000 | 2-1/8" | 56 | 411,000 | 82,200 | Reqd | |||||

| 3-0" | 76 | 274,000 | 54,800 | 456,667 | 91,333 | 2-1/4" | 57 | 484,000 | 96,800 | Reqd | |||||

| 3-1/4" | 83 | 339,000 | 67,800 | 565,000 | 113,000 | 2-1/2" | 64 | 529,000 | 105,800 | Reqd | |||||

These figures are for brand new rope. Age, wear, sunlight exposure, splices, and fraying will further reduce these figures over time

All hardware sizing is approximate where thimble size and rope thickness may require a larger shackle to fit properly

Heavy Duty Towing Thimbles are available to include NEWCO, Blue Line, NAVSEA, GN Rope Fittings, Rope Connectors, etc.

We also supply towing plates, wire rope assemblies, stud link chain, and additional hardware as required

Additional fiber and rope construction styles are available

When the bridle legs are 2x the length of the beam, the inside angle formed by the legs is very acute and the bridle leg strengths are additive

The inside bridle leg angle shall be 60deg or less where 30deg is very acute, but not to exceed 90deg

Most conservative is to approximately match the single leg strengths (DBN - Dyneema®) and design the inside bridle leg angle to be acute

Note a Mooring Bridle / Mooring Pendant Assembly can be configured based on the customer's application

Note a Anchor Chain Snubber Bridle / Anchor Chain Snubber Pendant Assembly can be configured based on the customer's application

For customer service and inquiries please call John 303-809-7274 or email john@denverrope.com

www.denverrope.com![]() Click Here to Download Our Mooring Bridle / Mooring Pendant Worksheet PDF to be also used for Anchor Chain Snubber Bridles & Anchor Chain Snubber Pendants

Click Here to Download Our Mooring Bridle / Mooring Pendant Worksheet PDF to be also used for Anchor Chain Snubber Bridles & Anchor Chain Snubber Pendants

![]() Click here to Download Our Boatline and Hardware Selection Guide PDF

Click here to Download Our Boatline and Hardware Selection Guide PDF

Mooring Hardware - At Denver Rope we offer a wide selection of Mooring Hardware in galvanized and stainless steel to include Thimbles, Swivel Hooks, Shackles, Snap Shackles, Swivels, and Anchor Chain Snubber Hooks. A selection of the anchor chain snubber hooks is depicted below.

Suncor Anchor Chain Snubber Hook Assembly

Suncor Stainless Steel Chain Eye Grab Hook. We also offer Galvanized Eye Grab Hooks for larger diameter chain applications. Clevis Style Hooks also available

Mantus Marine Original Stainless Steel Anchor Chain Hook

Mantus Marine M2 Stainless Steel Anchor Chain Hook

An example of a houseboat mooring pendant. Denver Rope can custom assemble this type of pendant using stainless steel wire rope, heavy duty wire rope thimbles, swages, shackles, and or anchor swivels as the customer specifies. Consider that 12-Strand Dyneema® Rope or Nylon Rope can be substituted for the wire rope shown.

An example of a heavy duty mooring pendant assembly with full length chafe guard protection. Note the piece of PVC tubing below the thimble. We can custom assembly your mooring line as per your specifications.

Custom mooring line assembly of 3/4” x 15’ solid black double braid nylon. Can substitute a dock line splice if connecting to a cleat or simply use a bitter end and a cleat hitch to secure the line.

Light duty stainless steel thimble splice and anchor shackle.

Utilize rope floats as required for your application including mooring lines, tow lines and tow bridles.

Light duty stainless steel thimble splice with a premium quality quick release snap shackle. Pull on the clasp to open the torsion bail. If your line is subject to twisting, then we recommend the use of a hook that is on a bearing. Make connections to your boat’s bow eye using such a hook.

Above - 1/2” & 5/8” lines with appropriately sized swivel eye hooks and anchor shackles. Hooks can be directly spliced to the thimbles.

Year-long / permanent type moorings connections are often made using a Safety Bolted Shackle as shown here. This 5/8” stainless steel shackle has a bolted connection along with a cotter pin for extra security along with a higher working load than standard bow shackles.

Whether a mooring pendant, anchor chain snubber, anchor line, etc., we offer standard light duty thimble splices that can be upgraded to heavy rope thimbles or heavy duty wire rope thimbles. We also offer regular duty galvanized thimbles and galvanized wire rope thimbles. Above is an example of a heavy duty wire rope thimble splice.

Above is a light duty thimble and a heavy rope thimble. We also offer regular duty galvanized thimbles and galvanized wire rope thimbles.

If your mooring is subject to a lot of water turbulence then we can provide a heavy duty rubber snubber as depicted above.

The picture above shows the other end of the pendant with a soft covered eye splice. Above is an example of a Mooring Pendant Assembly. 1-0” x 20ft white double braid nylon. One end with a heavy duty nylon thimble splice and a orange rope float. This customer wanted chafe guard along the rest of the line to include the thimble splice.

Above is an example of a Mooring Pendant Assembly. 1-0” x 20ft white double braid nylon. One end with a heavy duty nylon thimble splice and a orange rope float. This customer wanted chafe guard along the rest of the line to include the thimble splice.

Above is an example of a Anchor Chain Snubber Assembly. 7/8” x 20ft gold double braid nylon. One end with a stainless steel thimble splice to a 3/4” stainless steel bow shackle to a 3/8” anchor chain snubber hook. This customer did not want a bridle configuration, but two separate individual assemblies. The picture below shows the other end of the line with a 18” covered eye splice for a bow cleat.

Above is an example of a Anchor Chain Snubber Assembly. 7/8” x 20ft gold double braid nylon. One end with a stainless steel thimble splice to a 3/4” stainless steel bow shackle to a 3/8” anchor chain snubber hook. This customer did not want a bridle configuration, but two separate individual assemblies. The picture below shows the other end of the line with a 18” covered eye splice for a bow cleat.

Solid Rope Colors

Please continue to our ROPE COLORS webpage to consider the available rope colors and read the applicable restrictions. If not otherwise specified, Solid Black or White is typically the

default rope color. [Continue to ROPE COLORS webpage]

Custom Color Combinations

We offer 5 customizable rope patterns on the double braid rope machines. Please continue to our DENVER ROPE MIXER webpage to design your double braid custom color

combination and read the applicable restrictions. [Continue to DENVER ROPE MIXER webpage]

General Marine Hardware - For information on General Marine Hardware and subsequent detailed

webpages to include, Anchors, Anchor Chain, Galvanized Hardware, Stainless Steel Hardware, and Security Hardware:

[Continue to GENERAL MARINE HARDWARE webpage]

[Continue to ANCHORS webpage]

[Continue to ANCHOR CHAIN webpage]

[Continue to GALVANIZED HARDWARE—MAIN PAGE webpage. Scroll to the bottom of this webpage for

additional hardware specific links]

[Continue to STAINLESS STEEL HARDWARE—MAIN PAGE webpage. Scroll to the bottom of this webpage

for additional hardware specific links]

[Continue to SECURITY HARDWARE—MAIN PAGE webpage]

![]() Click Here to Download Our Mooring Bridle / Mooring Pendant Worksheet PDF to be also used for Anchor Chain Snubber Bridles & Anchor Chain Snubber Pendants

Click Here to Download Our Mooring Bridle / Mooring Pendant Worksheet PDF to be also used for Anchor Chain Snubber Bridles & Anchor Chain Snubber Pendants