The Best Custom Boat Lines, Custom Colored Ropes, & Special Assemblies made to Your Specifications

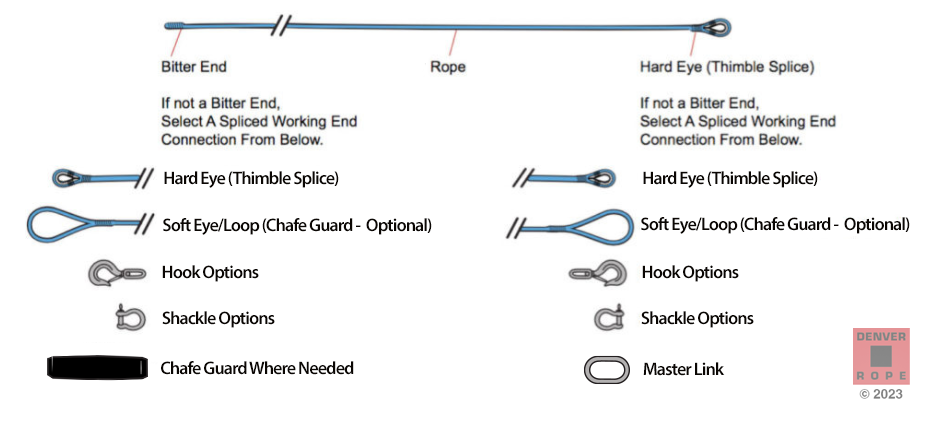

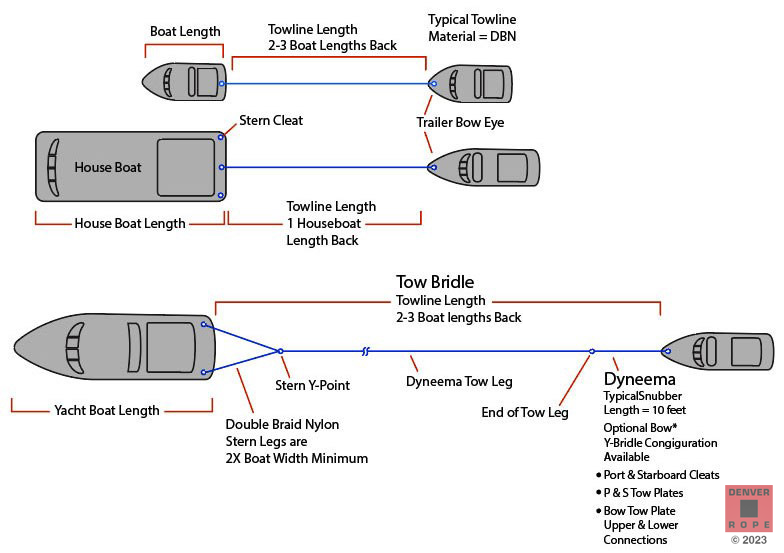

Single Leg Tow Line Diagram

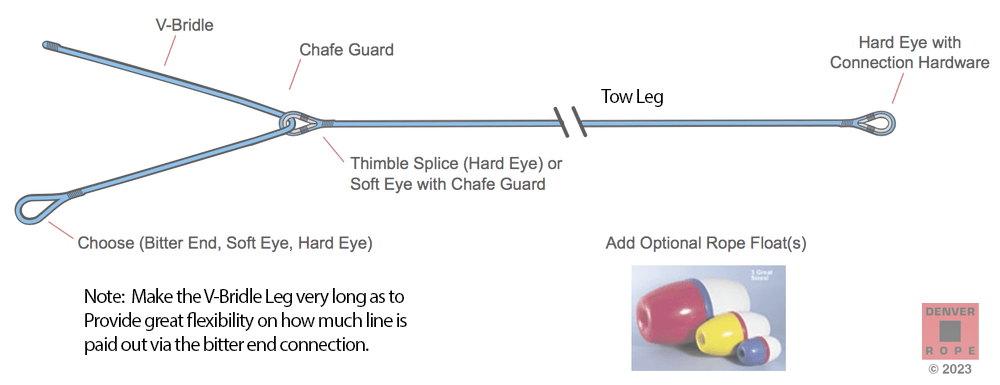

V-Shaped Tow Bridle Diagram

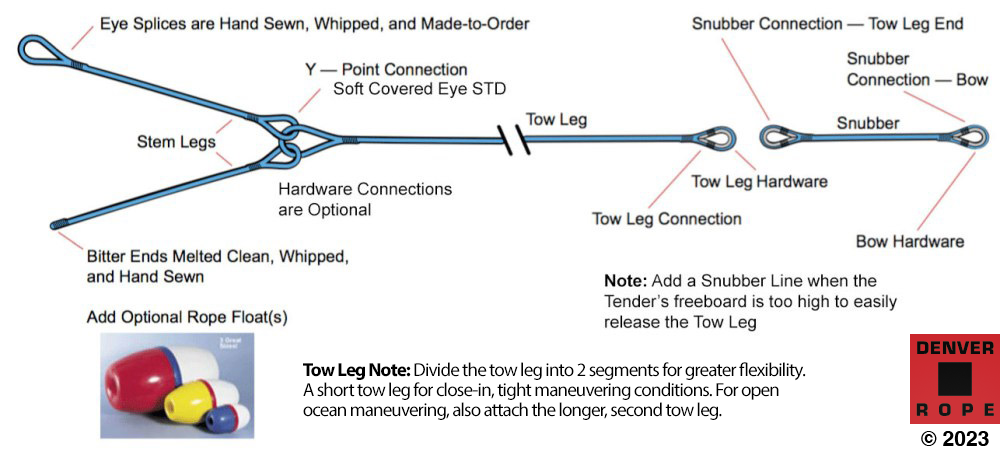

Y-Shaped Tow Bridle Diagram with Snubber Leg Option

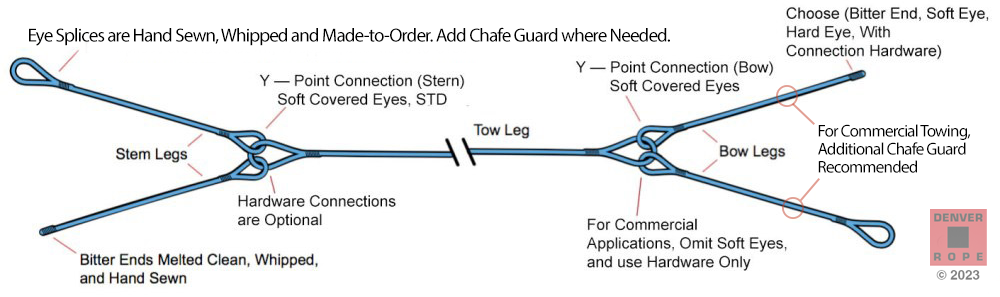

Y-Y-Shaped Tow Bridle Diagram

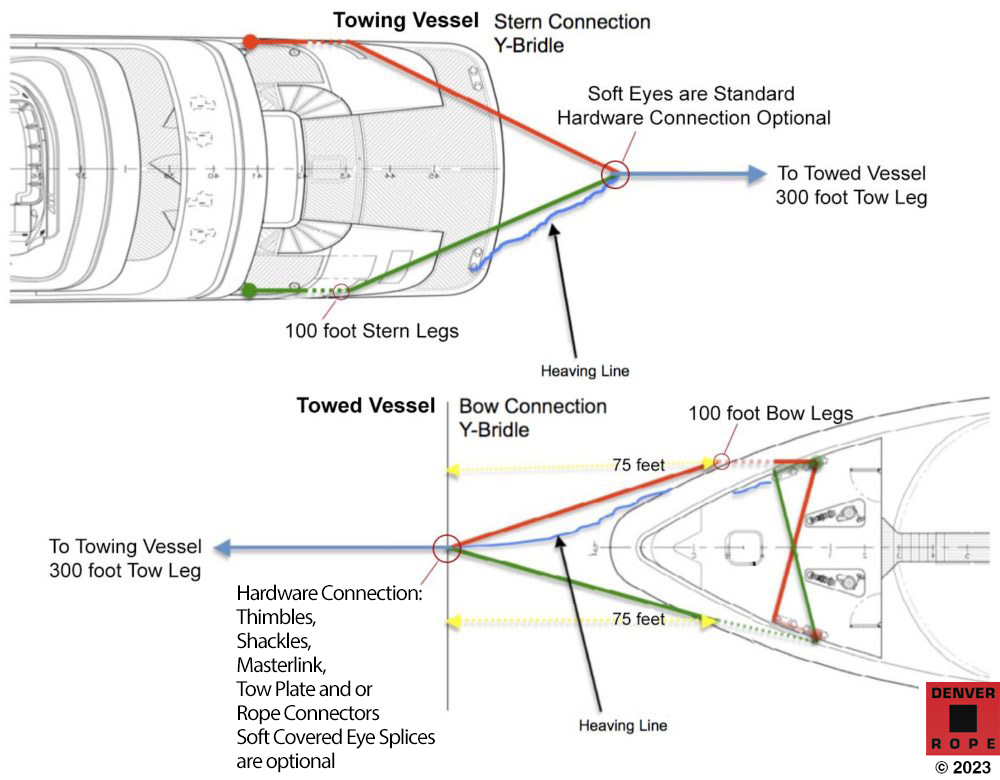

Y-Y-Shaped Tow Bridle Diagram Commercial M/Y Application

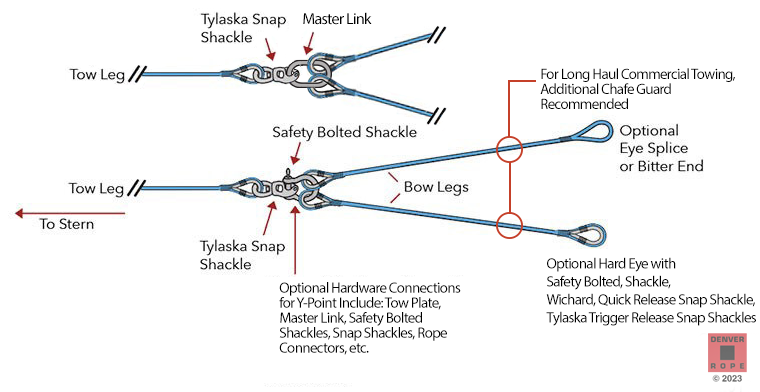

Y-Y Tow Bridle Bridle Diagram - Bow Connection Options

Pleasure Marine Tow Line Diagrams

Tow Line Diagram Notes

- Overall Tow Line Lengths are recommendations only subject to alternations, review, and approval by the Captain

- Overall Tow Line Lengths are effected by towing speed, weather conditions, and the resultant location of the towing boat's "wake sweet spot" of least turbulence

- Pull-In or Pay-Out Tow Line Rope and or Adjust Towing Speed as needed to optimize the towed boats location within the wake sweet spot

- The amount of force on the tow line is proportional to the towing speed squared (double the towing speed quadruples the force on the tow line)

- The Tow Lines for the Runabout and Houseboat are Single Leg Tow Lines

Denver Rope - Y-Bridle Strength Guide

| NYLON DOUBLE BRAID (DBN) Single Leg Tow Hawser |

Y-Bridle Configuration with each bridle leg at least 2x the boat's beam (min) | 12-STRAND DYNEEMA® Single Leg Tow Line to Join the Bridge Legs |

S/S Bow Shackle | S/S Safety Bolted Shackle | Galv Safety Bolted Shackle | Quick Release Snap Shackle | Trigger Release LB Shackle | Wire Rope or HD Thimble | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Diameter | Tensile | WLL 5:1 | Tensile | WLL 5:1 |

Diameter | Tensile | WLL 5:1 | ||||||||

| inches | mm | pounds | pounds | pounds | pounds | inches | mm | pounds | pounds | ||||||

| 1/2" | 13 | 7,300 | 1,460 | 12,167 | 2,433 | 5/16" | 8 | 12,300 | 2,460 | 1/2" | 1/2" | 7/16" | W2776 | T12 | Reqd |

| 5/8" | 16 | 14,600 | 2,920 | 24,333 | 4,867 | 3/8" | 10 | 17,600 | 3,520 | 5/8" | 5/8" | 1/2" | W2776 | T20 | Reqd |

| 3/4" | 19 | 19,000 | 3,800 | 31,667 | 6,333 | 1/2" | 13 | 30,600 | 6,120 | 1-0" | 3/4" | 5/8" | W2777 | T20 | Reqd |

| 7/8" | 22 | 28,100 | 5,620 | 46,833 | 9,367 | 5/8" | 196 | 47,500 | 9,500 | 1-1/4" | 7/8" | 3/4" | W2778 | T30 | Reqd |

| 1-0" | 25 | 33,200 | 6,640 | 55,333 | 11,067 | 3/4" | 19 | 58,000 | 11,600 | 1-0" | 7/8" | W2778 | T30 / T40 | Reqd | |

| 1-1/4" | 32 | 52,000 | 10,400 | 86,667 | 17,333 | 7/8" | 22 | 81,700 | 16,340 | 1-1/4" | 1-0" | T40 | Reqd | ||

| 1-1/2" | 38 | 74,000 | 14,800 | 123,333 | 24,667 | 1-0" | 25 | 98,100 | 19,620 | 1-1/4" | 1-1/8" | T40 | Reqd | ||

| 1-5/8" | 41 | 92,100 | 18,420 | 153,500 | 30,700 | 1-1/4" | 32 | 149,000 | 29,800 | 1-1/4" | T50 | Reqd | |||

| 1-3/4" | 45 | 109,500 | 21,900 | 182,500 | 36,500 | 1-1/2" | 38 | 205,000 | 41,000 | 1-1/2" | T50 | Reqd | |||

| 2-0" | 51 | 129,700 | 25,940 | 216,167 | 43,233 | 1-1/2" | 38 | 205,000 | 41,000 | 1-1/2" | Reqd | ||||

| 2-1/4" | 57 | 179,400 | 35,880 | 299,000 | 59,800 | 1-3/4" | 45 | 302,000 | 60,400 | 1-3/4" | Reqd | ||||

| 2-1/2" | 64 | 196,000 | 39,200 | 326,667 | 65,333 | 2-0" | 51 | 343,000 | 68,600 | 2-0" | Reqd | ||||

| 2-5/8" | 67 | 221,000 | 44,200 | 368,333 | 73,667 | 2-0" | 51 | 343,000 | 68,600 | 2-0" | Reqd | ||||

| 2-3/4" | 70 | 237,000 | 47,400 | 395,000 | 79,000 | 2-1/8" | 56 | 411,000 | 82,200 | Reqd | |||||

| 3-0" | 76 | 274,000 | 54,800 | 456,667 | 91,333 | 2-1/4" | 57 | 484,000 | 96,800 | Reqd | |||||

| 3-1/4" | 83 | 339,000 | 67,800 | 565,000 | 113,000 | 2-1/2" | 64 | 529,000 | 105,800 | Reqd | |||||

These figures are for brand new rope. Age, wear, sunlight exposure, splices, and fraying will further reduce these figures over time

All hardware sizing is approximate where thimble size and rope thickness may require a larger shackle to fit properly

Heavy Duty Towing Thimbles are available to include NEWCO, Blue Line, NAVSEA, GN Rope Fittings, Rope Connectors, etc.

We also supply towing plates, wire rope assemblies, stud link chain, and additional hardware as required

Additional fiber and rope construction styles are available

When the bridle legs are 2x the length of the beam, the inside angle formed by the legs is very acute and the bridle leg strengths are additive

The inside bridle leg angle shall be 60deg or less where 30deg is very acute, but not to exceed 90deg

Most conservative is to approximately match the single leg strengths (DBN - Dyneema®) and design the inside bridle leg angle to be acute

![]() Click here to Download Tow Bridle Worksheet PDF

Click here to Download Tow Bridle Worksheet PDF

![]() Click here to Download Our Boatline and Hardware Selection Guide PDF

Click here to Download Our Boatline and Hardware Selection Guide PDF

Thimble Eye Splice / Hard Eye — Use a thimble splice to protect the rope against chafing when using mechanical hardware connections like hooks and shackles. We specify Heavy Duty Wire Rope Thimbles when using 12-Strand Dyneema® Rope. We offer Light Duty and Heavy Duty Stainless Steel & Galvanized Thimbles.

Eye Splice / Soft Eye — Use a soft eye when connecting to a cleat. Cover the Eye in Chafe Guard (covered eye) to protect the rope against chafing. Soft Eye connections are lighter in weight than hardware connections. We typically specify covered eyes for tow bridle applications. Some customers will omit the eye splice and use a bitter end. We prefer to utilize lightweight soft covered eye splices to join the legs together forming a Y-Point Connection.

Single Leg Tow Line — As the name implies, a single piece of line is assembled with the required splices and or hardware on each end of the line. Specify how the tow line is connected to the stern of the towing vessel (eye splice or bitter end) and how the tow line is connected to the towed boat’s bow eye via a hard eye with hook or shackle. Use an eye splice if connecting to a cleat. The tow line can be fitted with a rope float(s).

V-Shaped Tow Bridle — Often for outboard applications, or where a lot of adjustment is required, one piece of line forms a V-Bridle Leg with a dock line eye splice (soft covered eye) on one end or both ends for connecting to the towing boat’s port and starboard stern cleats. Another option is to specify hard eye splices and hardware on each end of the V-Bridle Leg. Chafe guard can be applied to the middle of the V-Bridle line. A second longer piece of line (tow leg) is connected to the first in the middle via a smooth hard eye or soft eye splice. The other end of this line is connected to the towed boat’s bow eye via a hard eye with hook or shackle. Use an eye splice if connecting to a cleat. The V-Bridle portion might well be fitted with a rope float(s).

Y-Shaped Towing Bridle — The ultimate tow line solution; especially, for ocean going applications, is a Y-shaped custom towing bridle made to the customer’s specifications. Consider two separate pieces of line (Stern Bridle Legs) each with a dock line eye splice (soft covered eye) one for connecting to the boat’s port stern cleat and the other line for connecting to the starboard stern cleat. Alternatively, these lines might be specified with bitter ends to provide easier adjustment at the cleats. At the Y-Point, the stern legs are joined to a much longer third piece of line (tow leg) all via soft covered eye splices. Alter-natively, hard eye thimble splices, a master link / fish plate / tow plate, and required hardware can be substituted for the soft covered eye splices. The other end of the tow leg is connected to the towed boat’s bow eye via a hard eye with a hook or shackle. If the towed boat has a tall freeboard, for ease of disconnection from the tow leg, we can supply a short piece of line called a snubber line. The snubber can be provided with a hard or soft eye splice and hardware on each end of the line. From the bow, reach down with a safety pole, grab the snubber line, and release the tow leg. The tender / towed boat can be put underway with the snubber still attached. The stern bridle legs might well be fitted with a rope float(s). Note: Ropes floats can cause rooster tail splashing while underway. For this reason many Captains do not specify rope floats. However, if the crew is less experienced, rope floats do add a degree of peace of mind against the props cutting the bridle legs. Do not, backdown into the bridle.

Y-Y Shaped Towing Bridle — Usually applied where the tender / towed boat does not have a single connection on the bow, but does have port and starboard cleat connections. Utilize the same design concepts as the Y-Bridle Stern Legs, but now applied to the tender’s / towed boat’s port and starboard bow cleats. For heavy duty commercial applications, omit soft covered eye splices on the Y-Bow Bridle and utilize hard eyes and hardware to join the lines together at the Y-Point.

Tender Bow Tow Plate(s) — For ocean towing applications, the tender should have tow plate(s) installed on the bow.

Custom Made-to-Order Tow Lines & Tow Bridle Assemblies - Please consider that many of our tow line requests are for double braid nylon construction; however, we can generally utilize any of the rope materials described in Chapter 2 “Rope Selection Guide” and Chapter 5 “Bulk Rope”. Note there are additional diameters and rope lengths available upon request. All our tow lines are custom made-to -order, so we do not have part numbers for custom tow bridle assemblies, but description of components for each portion of the tow line / tow bridle assembly. Do not see what you are looking for, just ask. Yes, there are exceptions to every general rule stated above.

Bow & Stern Connection Considerations:

-

-

- Below is a typical list of bow connection methods:

- Trailer Winch Strap Bow U-Bolt (pleasure marine, lakes, and rivers. Less often open ocean)

- Bow Cleats (port / starboard for lake or open ocean)

- Bow Tow Plates (most often open ocean)

- Bow Single Hole

- Bow with Upper & Lower Holes

- Port / Starboard Single Hole

-

Additional Considerations:

-

-

-

- When specifying the hardware connections to the bow, take careful consideration as to the dimensions of the tow plate in order that the connecting hardware can fit

- Shackle pin diameter to be 1/8” smaller than the inside diameter of the hole collated with the working load limit of the shackle. In rare cases the hole may need to be honed larger so the pin can fit

- The outside dimensions of the hole / tow plate can not be so large that the shackle body can not

reach the pin or fit into the hole - Connections to cleats are via covered eye splices. Bitter ends can also be specified

- If the freeboard of the tender is too high to allow one to reach down and easy disconnect the tow

leg, a short snubber line is specified (single leg or 2 bow bridle legs). Use a pole to grab the snubber line(s) and release the long tow leg. Secure the snubber lines inside the tender’s bow and put under way with the snubber line(s) still attached

Typical shackle types include:

-

-

- Safety Bolted Shackle

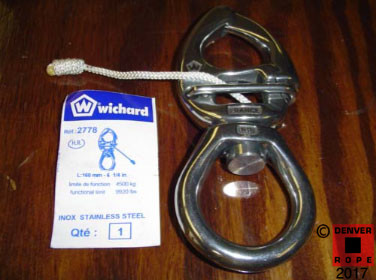

- Wichard Large Bail Quick Release Snap Shackle

Tylaska Large Bail Trigger Release Shackle - Stainless Steel is prevalent in Pleasure Marine and Open Ocean Applications; however, as

the boat size increases (commercial and heavy marine) galvanized hardware is more prevalent and economical given the size and WLL requirements

-

Y-Point Stern Considerations:

- The Y-Point stern bridle connection (2 stern legs to the tow leg) on the towing boat’s stern end of the tow bridle is most often done using soft covered eye splices. Rope turbulence is relatively benign in this location and omitting hardware keeps the weight down, is simple, and is more economical

- In heavy marine applications and for tow bridle disassembly purposes, the Y-Point bridle connection is often done using hardware: to include any combination of bolted safety shackles, rope connectors, towing thimbles, master link, pear link, fish plate, etc

- Rope floats can be added to the stern legs; however, many Captains have reported too much splashing from the rope floats and have taken them off. Ropes Floats are a matter of preference and application

-

-

Y-Point Bow Considerations:

-

-

- The Y-Point bow bridle connection (2 bow legs to the tow leg) on the tender’s end of the tow bridle

is most often done using soft covered eye splices for pleasure marine applications. Rope turbulence is a factor in this location, but omitting hardware keeps the weight down, is simple, and is more economical - For longer distance commercial ocean tows and heavy marine applications, the Y-Point bow bridle connection is often done using hardware: to include any combination of bolted safety shackles, rope connectors, towing thimbles, master link, pear link, fish plate, etc

- Rope floats are usually not a consideration

- The Y-Point bow bridle connection (2 bow legs to the tow leg) on the tender’s end of the tow bridle

-

Rope Material:

-

- For pleasure marine and lake applications double braid nylon (DBN) is typically chosen for the entire

assembly. As DBN sinks, rope floats can be added; however adding rope floats is optional - The Y-Point stern bridle connection (2 stern legs to the tow leg) on the towing boat’s stern end of

the tow bridle is most often done using DBN to provide shock abortion. Where applicable, some

Captains will specify the Bow Bridle as to also be in DBN - The remainder of the tow line assembly is typically provided in high performance, low stretch, 12-

Strand Dyneema®, which does float - For longer distance commercial ocean tows and heavy marine applications the rope material is as above, but can also include 8-strand rope construction. As an alternate to DBN and Dyneema®, 8- Strand Poly-Dan Blue or Maxiflex (polypropylene / polyester fiber blends) can be specified and this rope does float.

- For pleasure marine and lake applications double braid nylon (DBN) is typically chosen for the entire

Tow Bridle / Tow Line Design Considerations — Generally pay out enough tow line length to place the towed vessel behind the second wake of the towing vessel based on speed and weather conditions. This specification is more often applied to ocean towing, but less often when towing a recreational boat behind a houseboat on a calm lake. Select the working load of the tow line to be as much as the full weight of towed vessel. This specification is very important when towing during bad weather conditions and or where the wave action will create probable shock loads on the tow line to be equal to the towed vessel’s full weight. Again, this specification is more often applied to ocean towing. Select a Y-Shaped Towing Bridle for high performance towing applications (USGC recommended) as opposed to a single leg tow line, which is typical for lake towing applications / short term emergency tow line.

Working Load Considerations: For pleasure marine applications the working load is often chosen to be equal to the fully loaded weight of the towed vessel, but for larger vessels, ships, motor yachts, barges, and heavy equipment this conservative approach is not practical and too expensive. For lighter duty applications, practicality, pleasure marine, lake applications, tow line storage concerns, and or budgetary considerations the W.L. is often chosen to be 1/2, 1/3, or some other fraction of the fully loaded weight of the towed vessel.

We encourage the owner to consult with the boat manufacturer, naval architect, marine engineer, insurance company, and or other authorities as to provide their recommendations and industry guidelines. The vessel manufacturer should provide an engineered calculation (hydrodynamic ship modeling soft-ware) as to how much force is required to move / pull the vessel at slow speed for their specific vessel, ship, equipment. The WL of the towing assembly can be set to 2x the calculated force and the tensile strength set to 5x the WL. As opposed to calculating the force, a Static Bollard Pull Test can be per-formed to actually measure the pulling force (see below).

Consider the two commentaries below from two professional naval architects.

- There are various formulae that have been derived for calculating towing resistance of vessels in the water. While no doubt there are some rules of thumb used in the industry it would be a disservice to suggest there is a simplified ball park equation, as many variables can come into play such as displacement, waterline length, velocity, current, wind, wave height, wetted surface, windage area, shallow water effects etc. For an in depth study on the topic, I would direct you to Hydrodynamics in Ship Design by Saunders, published by the Society of Naval Architect and Marine Engineers. This is likely a bit heavier than what you are looking for. Some more practical formulae can be found in Tug Use in Port, A Practical Guide by Cpt Henk Hensen, published by The Nautical Institute (UK). There is a chapter devoted to Bollard Pull calculations which provide somewhat generalized formulae more likely to suit your customers’ needs.John Myers, P.E.

Principal Naval Architect

Hockema & Whalen Associates, Inc.

Naval Architects / Marine Engineers - There is also the Morrison Formulation, which is proportional to V^2 + skin friction (proportional to wetted area). Look it up in PNA (Principle of Naval Architecture); the equation is F = 1/2 rho Cd A V^2 where rho is the density of sea water, A is the frontal wetted surface area, and V is the towing velocity. When used, make sure the units are consistent. Cd for a ship can be around 0.1-0.2, so if you use 1.0, you should be enough conservative. Finally, I would strongly suggest you spend a bit of time on PNA and look at the viscous drag and wave making drag curves where the total force is the sum of the two.However, there is a more traditional and a practical approach (via testing) that is described by the American Bureau of Shipping (ABS) known as the Static Bollard Pull Test.Dominique Roddier, Phd

Marine Innovation & Technology

Naval Architects / Offshore Engineers

Long Distance - Heavy Use - Commercial Towing Considerations:

- Experience from the M/Y Iolanthe has shown that chafing of the lines at the Tender-End of the Tow

Bridle Assembly becomes of greater concern where there is much more relative water turbulence

compared to the Stern-End of the Tow Line. Therefore, we kindly recommend that soft covered eyes

that can be used for traditional pleasure marine grade Tow Leg to Bow Bridle and to Snubber Line

connections be replaced with commercial grade Hardware-to-Hardware connections - Typical Hardware-to-Hardware Combination Choices Include:

- Safety Bolted Shackle

- Master Link

- HD Thimbles

- Tylaska Large Bail Trigger Release Shackle

- Wichard Large Bail Quick Release Snap Shackle

- Stainless Steel is prevalent in Pleasure Marine and Open Ocean Applications; however, as

the boat size increases (commercial and heavy marine) galvanized hardware is more prevalent and more economical given the Size and WLL requirements

- Secondly, at the Tender-End of the Tow Bridle Assembly, we kindly recommend that the Snubber

Line and or Bow Bridle Lines be covered in Chafe Guard Material in order to protect the rope fibers

from chafing - Typical Chafe Guard Choices Include:

- Black Nylon Cordura Tublar Chafe Guard (standard chafe guard material)

- Light Grey Silver USCG Grade Chafe Guard (hand sewn to length and fit)

- We also offer Chafe Guard with hand sewn Velcro so one can replace and maneuver the deployment location

Example of a typical tow bridle assembly: To the left are the two black double braid nylon stern legs that connect to the stern of the towing boat’s cleats. The relatively long 12-strand Dyneema® tow leg is joined to the 2 stern legs using small soft covered eye splices, while the other end of the tow leg is provided with a hard eye splice using a heavy duty stainless steel wire rope thimble spliced to a stainless steel Wichard quick release snap shackle. At the top is the optional snubber line. The snubber line provides for ease of connection to the tow leg and allows the towed boat to be put underway with the snubber line still attached. Both ends of the snubber line are provided with heavy duty stainless steel wire rope thimbles. One thimble will receive the tow leg’s snap shackle while the other end of the snubber is provided with a stainless steel safety bolted shackle, which connects to the towed boat's bow eye. Note the additional sewing / whipping / lashing used to seat the rope within the thimble. As with all of our lines, our Tow Bridle Designs are fully customizable and made-to-order per the customer’s specifications.

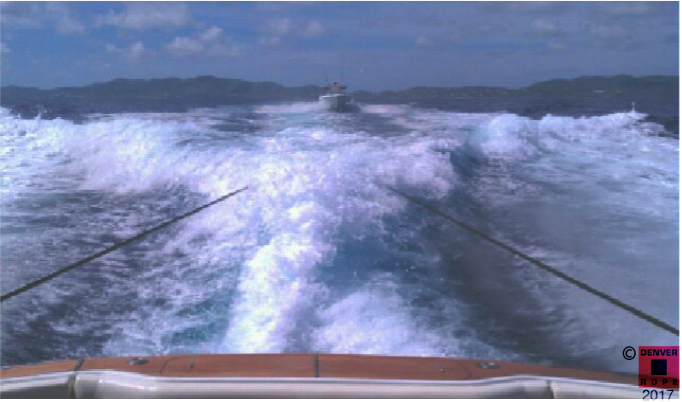

Above an example of a Fully Specified Ocean Tow Bridle, St. Croix USVI: 65 ft Hatteras Yacht towing a 32 ft Century. For this tow bridle the W.L. was chosen to be 10,000lbs minimum, which is the estimated fully loaded weight of the Century. Assembly: The two 40 ft stern legs are 1-1/4” black double braid nylon rope with 18” covered eyes for connecting to the Hatteras’ stern cleats. The other end of the sterns legs are each spliced with a small 6” covered eye splice used to join to a 6” covered eye splice of the relatively long 5/8” x 150 ft 12- strand Dyneema® tow leg. The other end of the tow leg is provided with a hard eye splice using a heavy duty stainless steel wire rope thimble spliced directly to a Tylaska T-30 large bail trigger release shackle. The T-30 connects to a 10 ft snubber line also made of 12-strand Dyneema® rope. The snubber line provides for ease of connection to the tow leg and allows the Century to be put underway with the snubber line still attached. Both ends of the snubber line are provided with heavy duty stainless steel wire rope thimbles. One thimble will receive the tow leg’s T-30 while the other end of the snubber is spliced directly to another Tylaska T-30 large bail swivel snap shackle, which connects to the Century’s bow eye.

Above is a picture of typical hardware used for pleasure marine applications. The hardware is stainless steel to include swivel eye hooks, bow shackles, and light duty thimble splices.

Above is a picture of a 1/2” stainless steel spring clip to a light duty stainless steel thimble splice

Above is a picture of stainless steel safety bolted shackle. Safety bolted shackles are preferred for ocean and heavy duty applications

Above is a picture of a stainless steel Wichard W2778 large bail quick release snap shackle

Rope Floats can be added if the nylon rope is required to float

Above is a picture of a stainless steel Tylaska T50 large bail trigger release shackle

Above is a picture 1-1/4” black double braid nylon covered 24” eye splice for a typical 1 of 2 stern leg cleat connections

Above is a picture of a typical Y-Bridle stern connection where the (2) 1-1/4” x 50 ft black DBN stern legs extend off to the right each with a 24” covered eye splice for connection to a stern cleat. Here the stern legs are joined to the 7/8” x 160 ft 12-strand Dyneema® tow leg using 6” covered eye splices.

Above is an example of a Y-Point connection where covered eye splices are substituted for thimble eye splices to a stainless steel master link. Additional hardware can be added if disassembly is required or for the quick release of the Dyneema® tow leg.

Above is an example of a Y-Point bow connection where the 7/8” x 160 ft tow leg extends off to the right.

The tow leg has a s/s wire rope thimble splice to a Tylaska T40 Trigger release shackle. Te tylaska shackle grabs the bolt of a 1-0” s/s safety bolted shackle. The safety shackle is used to collect the (2) 5/8” x 10 ft Dyneema® bow bridle legs each with a s/s wire rope thimble. When on the tender reach down with a pole and grab the bow bridle. Release the tow leg by opening the trigger, secure the bow legs and shackle inside the bow of the tender, put the tender underway. As discussed earlier, the Y- Point on the tender’s bow can be performed in a number of ways as per the Captain’s requirements. See previous discussion.

Above is an example of two bow bridle legs. The tender has a bow tow plate with two holes. Each of the Wichard’s W2778 snap shackles connects to a hole.

A 5/8” x 10 ft Dyneema® line connects to the top hole of the tow plate. A slightly longer 5/8” x 10’-6” Dyneema® line connects to the bottom hole of the tow plate. As discussed earlier, the connections to the tender’s bow tow plate can be performed in a number of ways as per the Captain’s requirements. See previous discussion.

We are pleased when a large custom made-to-order tow bridle assembly is shipped out to the customer

Above is a close-up picture of a Single Hole Bow Tow Plate . The critical dimensions are the inside diameter of the hole and the outside width of the tow plate. The shackle pin is typically specified to be an 1/8” smaller than the inside diameter, and the outside width can not be so wide / long that the shackle body can not reach the pin. If the freeboard is too high to allow one to reach down and easy disconnect the tow leg, a short snubber line is specified.

Above is a close-up picture of a Double Hole Bow Tow Plate where there is an upper hole and lower hole connection. In this case the lower bridle leg might be 6” longer than the top bridle leg. If the freeboard is too high to allow one to reach down and easy disconnect the tow legs, a short snubber line is specified. Notice how much more metal is used for the tow plates as compared to the trailer strap U-bolt. The two shackles are 5/8” stainless steel bow shackles. For ocean tows it is recommended to use safety bolted shackles.

Above is a picture of Port and Starboard - Single Hole Bow Tow Plates. The critical dimensions are the inside diameter of the hole and the outside width of the tow plate. The shackle pin is typically specified to be an 1/8” smaller than the inside diameter, and the outside width can not be so wide / long that the shackle body can not reach the pin. Again, if the freeboard is too high to allow one to reach down and easy disconnect the tow leg, a short snubber line is specified. In this case two snubber lines are required actually forming what is referred to as a Bow Y-Bridle.

Above is a close-up picture of one of the Single Hole Bow Tow Plates. The critical dimensions are the inside diameter of the hole and the outside width of the tow plate. The shackle pin is typically specified to be an 1/8” smaller than the inside diameter, and the outside width can not be so wide / long that the shackle body can not fitted to the pin. In this case the inside hole is too small for recommended safety bolted shackle and therefore should be honed to increase the diameter to allow for the shackle pin to fit. However, a Wichard W2778 was chosen instead, and the hole was left as-is.

Commercial Tow Bridles Experience Example - Indonesia, Malaysia, Philippines

We did a large commercial type Y-Y tow bridle for M/Y Princess Iolanthe out of Sabah, Malaysia. Where the estimate total tow distance is 12,000 NM in 2016. The (2) stern legs are 1-1/4” x 82 ft black double braid nylon each with 24” covered eye splices. On the other end at the Y-Point, two small covered eye splices are spliced directly to the 7/8” x 213 ft dyneema tow leg. The tender end of the tow leg is spliced directly to the covered eye splices of (2) 5/8” x 50 ft dyneema bow bridle legs. The bow legs are each connected to a 5/8” x 32 ft snubber leg using Tylaska T30 Trigger release shackles. The other end of the snubber lines are each connected to the tender’s port and starboard single hole tow plates via 7/8” s/s safety bolted shackles.

We have towed the dive tender around to Komodo, so that's around 2000NM, so far so good, just about some chaffing but nothing too bad

We are in the Banda Sea, Indonesia. So far we have towed roughly 3000NM on 50 days

Hope you are well, we have completed the 6000NM towing on our first trip, all in all it did really well, so strong! That not to say we didn’t have some scary moments in the Pacific, but I think the concern was always the dive cat tender flipping rather than the tow line failing

The tow line is looking in good condition, we have had some color fading on the Dyneema®, but I guess that is normal given the amount of UV that the line have been exposed to

Kind Regards,

Allen James Sutton Captain

M/Y Princess Iolanthe

Tow Bridle Deployment Preparations

The Y-Y Tow Bridle is carefully arranged on the AftnDeck for Safe Deployment by the Deck Crew. The Tow Leg Assembly is coiled in the foreground and the black double braid nylon Stern Y-Bridle legs are extended to the deck above for connection to the Cleats and Bits located there

The (2) Tylaska T-30s of the Y-Bow Bridle Assem-

bly are ready for connection to the Tender’s 2

Snubber Legs shown below

The (2) Snubber Legs are connected to the Tender’s (2) Bow Tow Plates via a S/S Safety Bolted Shackle. Safety Bolted Shackles are the preferred method used connect to the Bow Tow Plate(s), but a Quick Release Snap Shackle can be used also

The Tender’s (2) Snubber Legs are arranged on the Bow ready for connection to the (2) T-30s. Note the additional Chafe Guard placed along the entire length of the lines as needed for Long Commercial Tows. The Bow Bridle Assembly Working Load must be carefully considered so it is well coordinated with the Tow Bridle Assembly’s WLL

Tow Bridle Connection & Deployment

The Deck Crew, now carefully positioned, has connected the Y-Bow Bridle components the (2) Snubber

Legs of the Dive Tender and will carefully deploy the entire Y-Y Tow Bridle Assembly as the M/Y slowly

moves forward as not to apply a shock load to the Bridle Assembly

Close-Up Shot of the Y-Y Bridle now Fully Deployed

Now a Picturesque View of the Y-Y Bridle

V-Shaped Tow Bridle Example

Picture of a 5/8” Red DBN V-Shaped Tow Bridle Assembly. The Stern End of the V-Bridle is fed through the Tow Leg’s Thimble Splice. The Other End of the Tow Leg is at the Top Left. This customer has 2 outboard engines where the connections to the stern are via thru-the-hull U-bolts.

The customer selected a S/S Harness Clip to make the connections to the U-bolts on the stern and the same hardware set-up for the bow connection to the tender.

Consider that there are many ways to design a V-Bridle Leg: Double Ended Hard Eye Thimble Splices plus Hardware, Double Ended Soft Eye Splices to the Stern Cleat.

For Greater Deployment Options, a Long Single Eye Dock Line can be used where the Soft Eye Splice is connected to One Stern Cleat,

the Bitter End is fed thru the Tow Leg’s Thimble Splice, and then connected to the Stern’s opposite cleat. Pay Out / Pull-In the amount of line you need for the V-Bridle using the bitter end connection at the cleat.

3-Point Bow Bridle Example

Picture of a 3-Point Bow Bridle assembly using 3/8” 12-Strand Dyneema Rope directly spliced to 3 S/S Harness Clips. Set the overall length of the center connection to be 6ft for example, then using the same tape measure, determine the length to one of the side connection points, which will be longer.

This customer used 3 soft covered eye splices directly spliced to a S/S Master Link. The Tow Leg Hook will grab the Master Link. Consider that there are many ways to perform these connections (soft eyes, hard eyes, and many types of hardware (master links, bow shackles, swivel eye hooks, harness clips, snap shackles, etc.)

[Continue to SECURITY HARDWARE—MAIN PAGE webpage]

Solid Rope Colors

Please continue to our ROPE COLORS webpage to consider the available rope colors and read the applicable restrictions. If not otherwise specified, Solid Black or White is typically the default rope color. [Continue to ROPE COLORS webpage]

Custom Color Combinations

We offer 5 customizable rope patterns on the double braid rope machines. Please continue to our DENVER ROPE MIXER webpage to design your double braid custom color combination and read the applicable restrictions. [Continue to DENVER ROPE MIXER webpage]

Whipping Twine – Double Braid Lines are whipped with waxed seine twine at the eye splice throat and bitter end. The splicer will choose the closet whipping twine color match for your lines unless otherwise specified. Consider to select a different whipping twine color for each set of lines. Lines other than double braid construction may be whipped for an additional charge. [Continue to WHIPPING TWINE webpage]

Recovery Ropes / Tow Lines / Tow Bridles / Winch Lines – All share common features with Dock Lines, Anchor Lines, and Mooring Lines. Please visit the webpages below as needed.

Dock Lines and Dock Line Style Mooring Lines – Denver Rope custom assembles Dock Lines & Mooring Lines made from rope on our own braiding machines and then using our own professional rope splicers. We offer the following types of Dock Lines: Double Braid Nylon Dock Lines, 3-Strand Nylon Dock Lines, and 12-Strand Nylon Dock Lines, where Double Braid Nylon Dock Lines are by far the most popular rope construction we sell. Multiple Solid Colors and Patterns are available. Our Dock Lines are Custom Made-to-Order. [Continue to DOCK LINE webpage]

Anchor Lines and Anchor Line Style Mooring Lines – Denver Rope custom assembles Anchor Lines & Mooring Lines made from rope on our own braiding machines and then using our own professional rope splicers. We offer the following types of Anchor Lines: Double Braid Nylon Anchor Lines, 3-Strand Nylon Anchor Lines, 3-Strand Heat-Set Nylon Anchor Lines, 8-Strand Plaited Nylon Anchor Lines, and 12 -Strand Plaited Nylon Anchor Lines, where Double Braid Nylon Anchor Lines are by far the most popular rope construction we sell. Our Anchor Lines are Custom Made-to-Order. [Continue to ANCHOR LINE webpage]

![]() Click here to Download Tow Bridle Worksheet PDF

Click here to Download Tow Bridle Worksheet PDF

![]() Click Here to Download Our Boatline & Hardware Selection Guide PDF

Click Here to Download Our Boatline & Hardware Selection Guide PDF