The Best Custom Boat Lines, Custom Colored Ropes, & Special Assemblies made to Your Specifications

Common Definitions & Nautical Terms

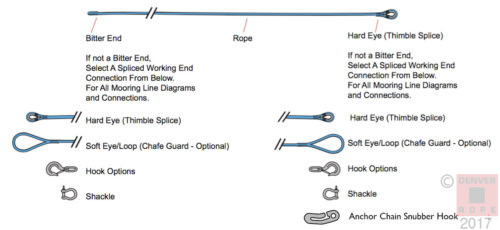

Thimble Eye Splice — Tow Lines like anchor lines are provided with a thimble eye splice on one end, which provides for chafe protection for connection to a shackle, swivel eye hook, or spring clip. The hook or clip connects the thimble eye of the tow line directly to the bow eye of the boat being towed. The bitter end (free end) of the tow line is made fast to the towing vessel’s stern cleat and the slack adjusted for tension (slack removed) using a cleat hitch. The tow line might well be fitted with a rope oat. One can also use a soft covered eye splice to connect to the stern cleat of the towing vessel. Simply select the required splices and hardware for each end of the tow line as required for your application.

Permanent or Shackle Connections — The connection between the tow line and the swivel eye hook or shackle can be a permanent connection (the hook is connected directly to the thimble) or a temporary connection (the hook is connected to the thimble via a shackle).

Hardware — As the W.L. of the Tow Line increase the type of hardware that may be used becomes more critical (HD Thimbles, Quick Release Snap Shackles, and Trigger Release Shackles).

Single Leg Tow Line — As the name implies, a single piece of line is assembled with the required splices and or hardware on each end of the line. Specify how the tow line is connected to the stern of the towing vessel (eye splice or bitter end) and how the tow line is connected to the towed boat’s bow eye via a hard eye with hook or shackle. The tow line might well be fitted with a rope float(s).

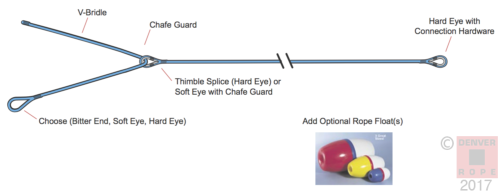

V-Shaped Tow Bridle — Usually for outboard applications; one piece of line with a dock line eye splice (soft covered eye) on each end for connecting to the towing boat’s port and starboard bow cleats. Another option is to specify hard eye splices and hardware on each end. Chafe guard is usually applied to the middle of this line. A second longer piece of line (tow leg) is connected to the first in the middle via a hard or soft eye splice. The other end of this line is connected to the towed boat’s bow eye via a hard eye with hook or shackle. The tow bridle might well be tted with a rope float(s).

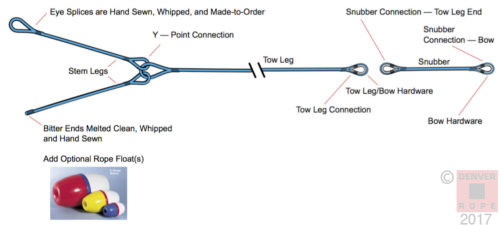

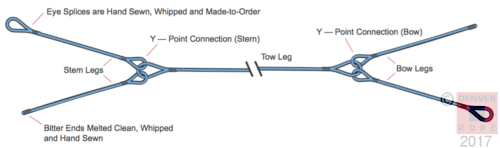

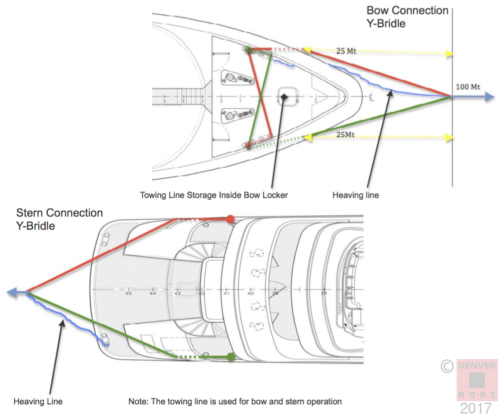

Y-Shaped Towing Bridle — The ultimate tow line solution; especially, for ocean going applications, is a Y-shaped custom towing bridle made to the customer’s specifcations. Consider two separate pieces of line (Stern Legs) each with a dock line eye splice (soft covered eye) one for connecting to the boat’s port stern cleat and the other line for connecting to the starboard stern cleat. Alternatively, these lines might be specified with bitter ends to provide easier adjustment at the cleat. At the Y-Point, the stern legs are joined to a much longer third piece of line (tow leg) all via soft covered eye splices. Alternatively, hard eye thimble splices, a master link / sh plate / tow plate, and required hardware can be substituted for the soft covered eye splices. The other end of the tow leg is connected to the towed boat’s bow eye via a hard eye with a hook or shackle. If the towed boat has a large freeboard and for ease of disconnection from the tow leg, we can supply a short piece of line called a snubber. The snubber can be provided with a hard or soft eye splice and hardware on each end of the line. Reach down with a safety pole, grab the snubber, and release the tow leg. The towed boat can be put underway with the snubber still attached. The tow bridle might well be fitted with a rope float(s).

Y-Y Shaped o in Bridle — Usually applied where the towed boat is relatively large like a yacht or sailboat and a single connection to the towed boat’s bow is not available. Utilize the same design concept as the Y-Bridle, but the stern legs are mirrored to provide two bow legs for connection to the towed boat’s port and starboard bow cleats. The tow bridle might well be fitted with a rope oat(s). Towing Hawser — Is a line used for towing purposes mostly used in heavy marine, commercial, and industrial applications. Towing Hawsers require specialized Shackles, Rope Connectors, Mooring Thimbles, Tow Plate, and or Towing Thimbles.

CONCERNING CUSTOM MADE-TO-ORDER TOW LINES - Please consider that many of our tow line requests are for double braid nylon construction; however, we can generally utilize any of the rope materials described in Chapter 2 “Rope Selection Guide” and Chapter 5 “Bulk Rope”. Note there are additional diameters and rope lengths available upon request. All our tow lines are custom made-to-order so we do not have part numbers for custom assemblies. Do not see what you are looking for, just ask.

Single Leg Tow Line Diagram

SV-Shaped Tow Bridle Diagram

SY-Shaped Tow Bridle Diagram

SY-Y Shaped Tow Bridle Diagram

SY-Y Shaped Tow Bridle Application

Tow Bridle/ Tow Line Design Considerations — Generally pay out enough tow line length to place the towed vessel behind the second wake of the towing vessel based on speed and weather conditions. This specification is more often applied to ocean towing, but less often when towing a recreational boat behind a houseboat on a calm lake. Select the working load of the tow line to be as much as the full weight of towed vessel. This specification is very important when towing during bad weather conditions and or where the wave action will create probable shock loads on the tow line to be equal to the towed vessel’s full weight. Again, this specification is more often applied to ocean towing. Select a Y-Shaped Towing Bridle for high performance towing applications (USGC recommended) as opposed to a single leg tow line, which is typical for lake towing applications.

Working Load Considerations — For pleasure marine applications the working load is often chosen to be equal to the fully loaded weight of the towed vessel, but for larger vessels, ships, large yachts, barges, and heavy equipment this conservative approach is not practical and too expensive. For lighter duty applications, practicality, pleasure marine, lake applications, tow line storage concerns, and or budgetary considerations the W.L. is often chosen to be 1/2, 1/3, or some other fraction of the fully loaded weight of the towed vessel.

We encourage the owner to consult with the manufacturer, naval architect, marine engineer, insurance company, and or other authorities of jurisdiction as to provide their recommendations and industry guidelines. The vessel manufacturer should provide an engineered calculation (hydrodynamic ship modeling software) as to how much force is required to move / pull the vessel at slow speed for their specific vessel, ship, equipment. The WL of the towing assembly can be set to 2x the calculated force and the tensile strength set to 5x the WL. As opposed to calculating the force, a Static Bollard Pull Test can be performed to actually measure the pulling force (see below).

Consider the two comments below from two professional naval architects. 1) There are various formulae that have been derived for calculating towing resistance of vessels in the water. While no doubt there are some rules of thumb used in the industry it would be a disservice to suggest there is a simplified ball park equation, as many variables can come into play such as displacement, waterline length, velocity, current, wind, wave height, wetted surface, windage area, shallow water effects etc. For an in depth study on the topic I would direct you to Hydrodynamics in Ship Design by Saunders, published by the Society of Naval Architect and Marine Engineers. This is likely a bit heavier than what you are looking for. Some more practical formulae can be found in Tug Use in Port, A Practical Guide by Captan Henk Hensen, published by The Nautical Institute (UK). There is a chapter devoted to Bollard Pull calculations which provide somewhat generalized formulae more likely to suit your customers’ needs. John Myers, P.E.

Principal Naval Architect Hockema & Whalen Associates, Inc. Naval Architects / Marine Engineers 2) There is also the Morrison Formulation, which is proportional to V^2 + skin friction (proportional to wetted area). Look it up in PNA (Principle of Naval Architecture); the equation is F = 1/2 rho Cd A V^2 where rho is the density of sea water, A the frontal area and V the towing velocity. When used, make sure the units are consistent. Cd for a ship can be around 0.1-0.2, so if you use 1.0, you should be enough conservative. Finally, I would strongly suggest you spend a bit of time on PNA and look at the viscous drag and wave making drag curves where the total force is the sum of the two. However, there is a more traditional and a practical approach (via testing) that is described by the American Bureau of Shipping (ABS) known as the Static Bollard Pull Test. Dominique Roddier, Phd Marine Innovation & Technology Naval Architects / Offshore Engineers

An example of a typical Y-Shaped Tow Bridle Assembly: To the left are the two black double braid nylon stern legs that connect to the stern of the towing boat’s cleats. The relatively long 12-strand dyneema tow leg is joined to the 2 stern legs using small soft covered eye splices, while the other end of the tow leg is provided with a hard eye splice using a heavy duty stainless steel wire rope thimble spliced to a stainless steel quick release snap shackle. At the top is the optional snubber line. The snubber line provides for ease of connection to the tow leg and allows the towed boat to be put underway with the snubber line still attached. Both ends of the snubber line are provided with heavy duty stainless steel wire rope thimbles. One thimble will receive the tow leg’s snap shackle while the other end of the snubber is provided with a stainless steel safety bolted shackle, which connects to the towed boat’s bow eye. Note the additional sewing / whipping / lashing used to seat the rope within the thimble. As with all of our lines, our Tow Bridle Designs are fully customizable and made-to-order per the customer’s speci cations.

Above an example of a Y-Shaped Tow Bridle Assembly: To the left are the two black double braid nylon stern legs that connect to the stern of the towing boat’s cleats. The relatively long 12-strand dyneema tow leg is joined to the 2 stern legs using small soft covered eye splices, while the other end of the tow leg is provided with a hard eye splice using a heavy duty stainless steel wire rope thimble spliced to a stainless steel trigger release shackle. Note the additional sewing / whipping / lashing used to seat the rope within the thimble. As with all of our lines, our Tow Bridle Designs are fully customizable and made-to-order per the customer’s specifications.

An example of a Fully Specified Ocean Tow Bridle: 58 ft Sovran Yacht by Tiara towing a 24 ft Center Console by Everglades The bridle’s working load was chosen to be 4,500 lbs, which is the estimated fully loaded weight of the center console. Notice that the center console stays in the middle of the wake even as the Tiara is making a port side turn. Assembly: The two sterns legs are 7/8” x 40 ft black double braid nylon. The connection to the Tiara’s stern cleats are via 36” covered eye splices with the other ends being spliced with heavy duty stainless steel wire rope thimbles and stainless steel snap shackles. The longer tow leg is 1/2” x 85 ft blue 12- strand dyneema / amsteel with each end spliced with a heavy duty stainless steel wire rope thimble. One thimble will receive the two snap shackles from the stern legs while the other end of the tow leg is spliced with a stainless steel snap shackle. This snap shackle connects to a 10 ft snubber line made of blue 12-strand dyneema amsteel. The snubber line provides for ease of connection to the tow leg and allows the center console to be put underway with the snubber still attached. One end of the snubber has a 24” covered eye splice, which connects to the tow leg’s snap shackle. The other end of the snubber is spliced with a heavy duty stainless steel wire rope thimble and a stainless steel snap shackle, which connects to the center console’s bow eye. Options This bridle can be disassembled because the Y-point is mechanically joined together with snap shackles. Other customers may not need this feature and specify that the stern and tow legs be spliced together using soft covered eye splices. Some customers specify the stern legs with bitter ends as opposed to covered eye splices. Too many options exist to list here, but the above illustrates a standard example of what can be done.

Above an example of a Y-Shaped Tow Bridle Assembly: To the left are the two black double braid nylon stern legs that connect to the stern of the towing boat’s cleats. The relatively long 12-strand dyneema tow leg is joined to the 2 stern legs using small soft covered eye splices, while the other end of the tow leg is provided with a hard eye splice using a heavy duty stainless steel wire rope thimble spliced to a stainless steel trigger release shackle. Note the additional sewing / whipping / lashing used to seat the rope within the thimble. As with all of our lines, our Tow Bridle Designs are fully customizable and made-to-order per the customer’s specifications.

An example of a Fully Specified Ocean Tow Bridle: 58 ft Sovran Yacht by Tiara towing a 24 ft Center Console by Everglades The bridle’s working load was chosen to be 4,500 lbs, which is the estimated fully loaded weight of the center console. Notice that the center console stays in the middle of the wake even as the Tiara is making a port side turn. Assembly: The two sterns legs are 7/8” x 40 ft black double braid nylon. The connection to the Tiara’s stern cleats are via 36” covered eye splices with the other ends being spliced with heavy duty stainless steel wire rope thimbles and stainless steel snap shackles. The longer tow leg is 1/2” x 85 ft blue 12- strand dyneema / amsteel with each end spliced with a heavy duty stainless steel wire rope thimble. One thimble will receive the two snap shackles from the stern legs while the other end of the tow leg is spliced with a stainless steel snap shackle. This snap shackle connects to a 10 ft snubber line made of blue 12-strand dyneema amsteel. The snubber line provides for ease of connection to the tow leg and allows the center console to be put underway with the snubber still attached. One end of the snubber has a 24” covered eye splice, which connects to the tow leg’s snap shackle. The other end of the snubber is spliced with a heavy duty stainless steel wire rope thimble and a stainless steel snap shackle, which connects to the center console’s bow eye. Options This bridle can be disassembled because the Y-point is mechanically joined together with snap shackles. Other customers may not need this feature and specify that the stern and tow legs be spliced together using soft covered eye splices. Some customers specify the stern legs with bitter ends as opposed to covered eye splices. Too many options exist to list here, but the above illustrates a standard example of what can be done.

An example of a Fully Specified Ocean Tow Bridle: 140 ft Sailboat towing a 25 ft 6,000lb recreational power boat in the Caribbean

The Two Sterns Legs are 7/8” x 50 ft black double braid nylon and extend off to the left. Each bitter end is whipped and melted clean. The captain will adjust tension and length of the stern legs to the towing vessel’s cleats mounted on its stern. Note the chafe protection provided on each of the 6” soft eye splices. The 3/4” x 140 ft 12- strand dyneema tow leg extends off to the right.

An example of a Fully Specified Ocean Tow Bridle: 140 ft Sailboat towing a 25 ft 6,000lb recreational power boat in the Caribbean

The Two Sterns Legs are 7/8” x 50 ft black double braid nylon and extend off to the left. Each bitter end is whipped and melted clean. The captain will adjust tension and length of the stern legs to the towing vessel’s cleats mounted on its stern. Note the chafe protection provided on each of the 6” soft eye splices. The 3/4” x 140 ft 12- strand dyneema tow leg extends off to the right.

Another view. The 2 Stern Legs extend to the right as the 3/4” x 140 ft 12– Strand Dyneema Tow Leg extends off to the left. All of our double braid nylon splices are hand sewn and whipped for extra holding power. Note the quality of workmanship of the splicing and whipping. Another option will have the three legs joined together using stainless steel thimble splices “hard eyes” to a stainless steel master link. Customize your towing line for your Yacht, Houseboat, or any vessel that may require a custom line.

Another view. The 2 Stern Legs extend to the right as the 3/4” x 140 ft 12– Strand Dyneema Tow Leg extends off to the left. All of our double braid nylon splices are hand sewn and whipped for extra holding power. Note the quality of workmanship of the splicing and whipping. Another option will have the three legs joined together using stainless steel thimble splices “hard eyes” to a stainless steel master link. Customize your towing line for your Yacht, Houseboat, or any vessel that may require a custom line.

End view - 3/4” x 140 ft Tow Leg. This end provided with a heavy duty stainless steel thimble splice and a large 1-1/4” stainless steel bolted safety shackle for connection to the snubber shown below. Note the additional whipping used to keep the dyneema line seated in place. We specialize in stainless steel hardware for large boats.

End view - 3/4” x 140 ft Tow Leg. This end provided with a heavy duty stainless steel thimble splice and a large 1-1/4” stainless steel bolted safety shackle for connection to the snubber shown below. Note the additional whipping used to keep the dyneema line seated in place. We specialize in stainless steel hardware for large boats.

3/4” x 10 ft Dyneema Snubber. Each end spliced with a heavy duty stainless steel thimble. One end provided with a 3/4” stainless steel bow shackle for connection to the towed vessel’s bow. The other thimble splice connects to the bolted shackle shown above. Customers can add rope oats, additional hardware, and or substitute another type of rope construction to t their application. Call Denver Rope today!

3/4” x 10 ft Dyneema Snubber. Each end spliced with a heavy duty stainless steel thimble. One end provided with a 3/4” stainless steel bow shackle for connection to the towed vessel’s bow. The other thimble splice connects to the bolted shackle shown above. Customers can add rope oats, additional hardware, and or substitute another type of rope construction to t their application. Call Denver Rope today!

Above an example of a Fully Specified Ocean Tow Bridle, St. Croix USVI: 65 ft Hatteras Yacht towing a 32 ft Century. For this tow bridle the W.L. was chosen to be 10,000lbs minimum, which is the estimated fully loaded weight of the Century.

Assembly: The two 40 ft stern legs are 1-1/4” black double braid nylon rope with 18” covered eyes for connecting to the Hatteras’ stern cleats. The other end of the sterns legs are each spliced with a small 6” covered eye splice used to join to a 6” covered eye splice of the relatively long 5/8” x 150 ft 12- strand dyneema tow leg. The other end of the tow leg is provided with a hard eye splice using a heavy duty stainless steel wire rope thimble spliced directly to a Tylaska T-30 large bail trigger release shackle. The T-30 connects to a 10 ft snubber line also made of 12-strand dyneema rope. The snubber line provides for ease of connection to the tow leg and allows the Century to be put underway with the snubber line still attached. Both ends of the snubber line are provided with heavy duty stainless steel wire rope thimbles. One thimble will receive the tow leg’s T-30 while the other end of the snubber is spliced directly to another Tylaska T-30 large bail swivel snap shackle, which connects to the Century’s bow eye.

All of our towing bridles and lines are customer specified, made-to-order, and manufactured in the USA!

Above an example of a typical Y-Shaped Tow Bridle Assembly: To the left are the two black double braid nylon stern legs that connect to the stern of the towing boat’s cleats. The relatively long 12-strand dyneema tow leg is joined to the 2 stern legs using small soft covered eye splices, while the other end of the tow leg is provided with a hard eye splice using a heavy duty stainless steel wire rope thimble spliced to a stainless steel quick release snap shackle. At the top is the optional snubber line. The snubber line provides for ease of connection to the tow leg and allows the towed boat to be put underway with the snubber line still attached. Both ends of the snubber line are provided with heavy duty stainless steel wire rope thimbles. One thimble will receive the tow leg’s snap shackle while the other end of the snubber is provided with a stainless steel safety bolted shackle, which connects to the towed boat’s bow eye. Note the additional sewing / whipping / lashing used to seat the rope within the thimble. As with all of our lines, our Tow Bridle Designs are fully customizable and made-to-order per the customer’s specifications.

Above an example of a Fully Specified Ocean Tow Bridle, St. Croix USVI: 65 ft Hatteras Yacht towing a 32 ft Century. For this tow bridle the W.L. was chosen to be 10,000lbs minimum, which is the estimated fully loaded weight of the Century.

Assembly: The two 40 ft stern legs are 1-1/4” black double braid nylon rope with 18” covered eyes for connecting to the Hatteras’ stern cleats. The other end of the sterns legs are each spliced with a small 6” covered eye splice used to join to a 6” covered eye splice of the relatively long 5/8” x 150 ft 12- strand dyneema tow leg. The other end of the tow leg is provided with a hard eye splice using a heavy duty stainless steel wire rope thimble spliced directly to a Tylaska T-30 large bail trigger release shackle. The T-30 connects to a 10 ft snubber line also made of 12-strand dyneema rope. The snubber line provides for ease of connection to the tow leg and allows the Century to be put underway with the snubber line still attached. Both ends of the snubber line are provided with heavy duty stainless steel wire rope thimbles. One thimble will receive the tow leg’s T-30 while the other end of the snubber is spliced directly to another Tylaska T-30 large bail swivel snap shackle, which connects to the Century’s bow eye.

All of our towing bridles and lines are customer specified, made-to-order, and manufactured in the USA!

Above an example of a typical Y-Shaped Tow Bridle Assembly: To the left are the two black double braid nylon stern legs that connect to the stern of the towing boat’s cleats. The relatively long 12-strand dyneema tow leg is joined to the 2 stern legs using small soft covered eye splices, while the other end of the tow leg is provided with a hard eye splice using a heavy duty stainless steel wire rope thimble spliced to a stainless steel quick release snap shackle. At the top is the optional snubber line. The snubber line provides for ease of connection to the tow leg and allows the towed boat to be put underway with the snubber line still attached. Both ends of the snubber line are provided with heavy duty stainless steel wire rope thimbles. One thimble will receive the tow leg’s snap shackle while the other end of the snubber is provided with a stainless steel safety bolted shackle, which connects to the towed boat’s bow eye. Note the additional sewing / whipping / lashing used to seat the rope within the thimble. As with all of our lines, our Tow Bridle Designs are fully customizable and made-to-order per the customer’s specifications.Example No.1 A 55 ft Sport sh towing a 25 ft 5,000 lb center console boat to / from FL to Bahamas. In this case we would recommend a fully specified Y-shaped towing bridle with a safe W.L. of approximately equally to the 100% full weight of the center console. In this example we would specify 2 Y-legs at 7/8” x 50 ft double braid nylon for connecting to the sport sh’s stern cleats. Here the connection to the cleats can be via bitter ends using a figure eight knot or covered dock line eye splices. Then we have a 1/2” x 150 ft 12-strand dyneema tow leg with a thimble and bearing shackle connection to the center console’s bow. Very often the captain will choose to include an optional snubber line so the towed vessel can be quickly disconnected from the tow leg and put underway even with the snubber line still attached to the bow. Comment: reducing the W.L. to 75% will reduce the stern leg rope diameter to 3/4” double braid nylon & the tow leg can be changed from 12-strand dyneema to 3/4” double braid. Consider adding rope oats. Example No.2 A 75 ft Houseboat towing a 22 ft 3,800 lb wakeboard boat on Lake Powell. In this case we would recommend a single leg tow line with a safe W.L. of approximately 50% of the full weight of the wakeboard boat (2,000 lbs). In this example we would specify a 5/8” x 75 ft double braid nylon tow line. Here the connection to the houseboat’s stern cleats can be via a bitter end using a cleat hitch or a covered dock line eye splice. On the opposite end of the tow line we would specify a swivel eye hook for connection to the wakeboard boat’s bow. Very often the captain will choose to place a rope oat near the houseboat’s stern and even another rope oat near the wakeboard boat’s bow. Comment: reducing the W.L. to a 33% will reduce the rope diameter to 1/2”

Towing on a Lake? We custom assemble single leg tow lines for recreational and commercial towing applications like this one on Lake Powell, Utah / AZ.

Towing on a Lake? We custom assemble single leg tow lines for recreational and commercial towing applications like this one on Lake Powell, Utah / AZ.