The Best Custom Boat Lines, Custom Colored Ropes, & Special Assemblies made to Your Specifications

Common Definitions & Nautical Terms

Rope is a length of fibers twisted or braided together to provide a means of connecting, securing, and or pulling objects together.

Wire Rope is a rope constructed of wire strands instead of fibers. Line is a nautical term used to describe a length of rope used for marine and boating purposes. Mooring Line is a nautical term used to describe a length of rope (i.e. a line) used to moor (connect / fasten / make fast) a marine vessel to dock, pile, wharf, buoy field, the shoreline, lake bottom, and or sea bottom.

Mooring Line is a general term to include both Anchor and Dock Lines and mostly used in heavy marine, commercial, and industrial applications to describe a large vessel’s dock lines.

Hawser is a similar nautical term used to describe a length of rope (i.e. a line) used to moor (connect / fasten / make fast) a marine vessel to dock, pile, wharf, and mostly used in heavy marine, commercial, and industrial applications.

Dock Lines are used to Moor (connect / fasten) or Make Fast a boat to a dock (dock lines) or a permanent mooring (mooring lines) like a pile, pier, or wharf. Most often the connecting points are cleats, but not always. Boat fenders are employed to cushion the movement of the boat against the mooring.

Anchor Lines are used to temporarily Moor (connect / fasten) or Make Fast a boat to a lake or sea bottom.

Mooring Pendant is a relatively short length of line used to connect a vessel to a mooring buoy usually via the boat’s bow eye or bow cleats. The boat can free wheel about the mooring depending on the wind direction.

Tow Lines are used to tow a vessel behind a larger boat like a houseboat or yacht. Similarly, a Towing Hawser is a line used for towing purposes mostly used in heavy marine, commercial, and industrial applications.

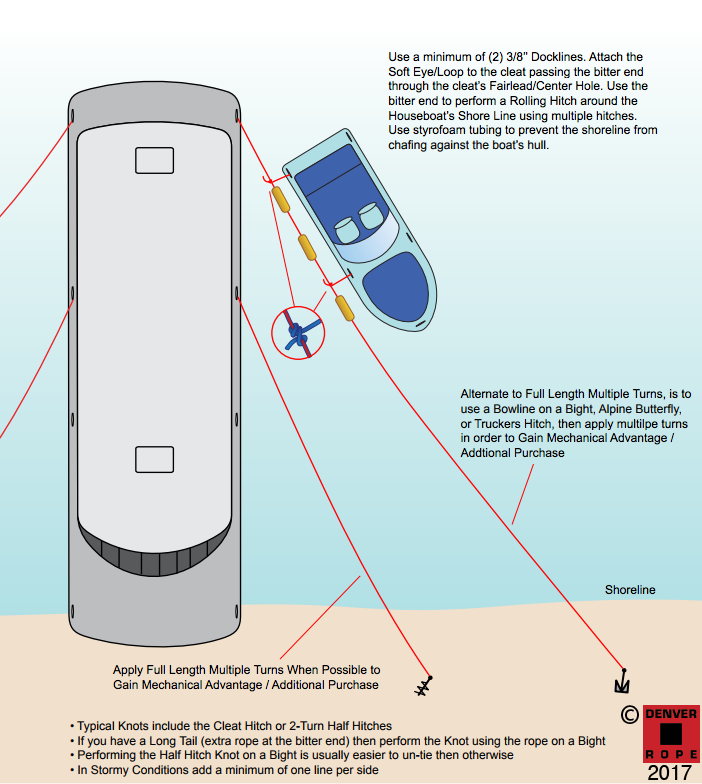

Shore Lines are used to temporarily Moor (connect / fasten) or Make Fast a boat to the shoreline. These mooring lines can be long dock lines and or anchor lines often applied in house boating applications.

Storm Lines are an extra set of mooring lines brought out of storage when the weather gets rough and utilized to provide an additional safety margin (just in case).

Traveling Lines are an extra set of mooring lines used to provide flexibility for docking conditions when traveling from port to port as your normal dock lines might well be too customized for your slip arrangement back home.

Boat Fender Lines / Whips are smaller diameter lines used to hold your boat fenders in place against your boat’s haul. Boat fender lines are provided with a bitter on each end or with a small loop on one end.

Bitter End is the end of a line where no splices are provided. The bitter end is often seized (melted clean and whipped) to prevent fraying of the rope fibers.

Eye Splice / Loop / Soft Eye Dock Lines and Mooring Lines are provided with a spliced loop on one end (even both ends), which provides for an easy method for making fast around a cleat, pile, bolted eye ring, etc. While the bitter end (free end) of the dock line is made fast to another cleat and the slack adjusted for tension (slack removed) using a cleat hitch.

Chafe Protection / Covered Eye Use Leather, Nylon Cordura Tubing, or Dipping to increase the life span of your lines as they rub against cleats, chocks, and your moorings. Chafe protection is most often used on eye splices, but can be used to protect other sections of the line below the throat of the eye splice (fairlead areas for example). Covered Eyes are a must for long term mooring applications. Is your boat moored in a slip? Then cover those eyes.

Thimble Splice / Hard Eye is a shapely grooved piece of metal (galvanized or stainless steel for example) which provides chafe protection against the connecting hardware like shackles, hooks, etc. The rope makes a tight bend around the thimble’s outside grooved channel and is spliced back into itself. The hardware will rub not on the rope, but on the inside smooth surface of the thimble. Anchor and Tow Lines most often have at least one thimble splice. Mooring Thimbles and Towing Thimbles are used in specialized heavy marine, commercial, and industrial applications (Hawser). Working Load is a fraction of the rope’s tensile / breaking strength used to provide a safety factor to account for splices, fiber wear, usage, knots, application, etc. Most often the fraction is at least 1:5, but can be larger depending on the application and fiber characteristics. Never exceed the safe working load of the rope / line.

Working Load Considerations For pleasure marine applications the working load is often chosen to be equal to the fully loaded weight of the towed vessel, but for larger vessels, ships, large yachts, barges, and heavy equipment this conservative approach is not practical and too expensive. For lighter duty applications, practicality, pleasure marine, lake applications, tow line storage concerns, and or budgetary considerations the W.L. is often chosen to be 1/2, 1/3, or some other fraction of the fully loaded weight of the towed vessel. We encourage the owner to consult with the manufacturer, naval architect, marine engineer, insurance company, and or other authorities of jurisdiction as to provide their recommendations and industry guidelines. The manufacturer may have to provide an engineered calculation (hydrodynamic ship modeling software) as to how much force is required to move / pull the vessel at slow speed for their specific vessel, ship, equipment. The WL of the towing assembly can be set to 2x the calculated force and the tensile strength set to 5x the WL. As opposed to calculating the force, a Static Bollard Pull Test can be performed to actually measure the pulling force.

Aft refers to the back end of the boat (toward the stern). Alongside refers to the side of the boat. Ballast refers to weight placed inside a boat to achieve the desired trim or draft.

Beam refers to the width (breadth) of a boat.

Bilge refers to the lower inner compartment of a boat’s hull. A bilge pump might be placed in this location.

Bitt refers to a post or bollard on a boat or dock area where mooring lines are secured to. There are single bits, double bitts, and horned bitts.

Capstan refers to a hand cranked or machine driven, vertical, spindle mounted drum that winds mooring lines and anchor rodes, which contrasts with a horizontal mounted machine called a windlass.

Bow refers to the front end of the boat.

Bridle refers to a V-shaped or Y-shaped line arrangement connected to the boat’s port and starboard cleats or bitts used during towing or mooring.

Buoy refers to a floating object used to identify a location (a navigation aid).

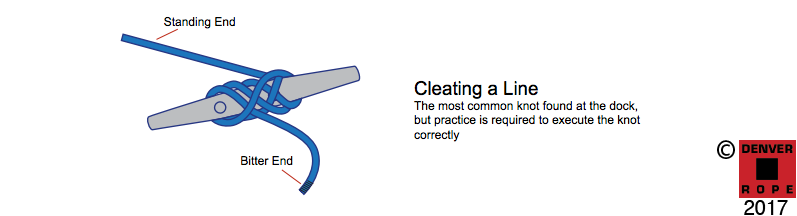

Cleat refers to a forged metal fitting with two project horns secured to a boat’s hull or dock area where a mooring line is made fast to (cleating a line using a cleat hitch). Kevel is another term for a cleat. Some cleats have a center hole or chock.

Chock refers to a forged metal fitting providing a location and guidance for mooring lines to pass though. Draft refers to the depth of a boat’s keel below the waterline.

Fairlead refers to an assembly of roller bearings facilitating the movement of a cable in any direction. A chock has similar functionality for rope applications.

Boat Fender refers to an object that absorbs and provides cushioning between a boat and the dock. Buoys can also provide this function.

Fish Plate / Towing Plate refers to forged triangular shaped plate with three holes that facilitates the ease of mechanical connection between a tow bridle and the tow line / hawser.

Freeboard refers to the distance between the waterline and the deck of a boat. Keel refers to the lowest structural member that runs the entire length of a boat along the centerline.

Hull refers to the main body of a boat that provides floatation.

Nautical Mile refers to a unit of measure equal to 6076 feet or 1852 meters or 1.15 statute miles.

Padeye refers to angular steel plate often affixed to the deck of a boat with a hole that provides for a mechanical connection for lines and or cables.

Shackle refers to a U-Shaped piece of metallic hardware with a threaded screw pin which provides for a mechanical connection between pieces of equipment like chain and an anchor.

Rope is a length of fibers twisted or braided together to provide a means of connecting, securing, and or pulling objects together.

Wire Rope is a rope constructed of wire strands instead of fibers. Line is a nautical term used to describe a length of rope used for marine and boating purposes. Mooring Line is a nautical term used to describe a length of rope (i.e. a line) used to moor (connect / fasten / make fast) a marine vessel to dock, pile, wharf, buoy field, the shoreline, lake bottom, and or sea bottom.

Mooring Line is a general term to include both Anchor and Dock Lines and mostly used in heavy marine, commercial, and industrial applications to describe a large vessel’s dock lines.

Hawser is a similar nautical term used to describe a length of rope (i.e. a line) used to moor (connect / fasten / make fast) a marine vessel to dock, pile, wharf, and mostly used in heavy marine, commercial, and industrial applications.

Dock Lines are used to Moor (connect / fasten) or Make Fast a boat to a dock (dock lines) or a permanent mooring (mooring lines) like a pile, pier, or wharf. Most often the connecting points are cleats, but not always. Boat fenders are employed to cushion the movement of the boat against the mooring.

Anchor Lines are used to temporarily Moor (connect / fasten) or Make Fast a boat to a lake or sea bottom.

Mooring Pendant is a relatively short length of line used to connect a vessel to a mooring buoy usually via the boat’s bow eye or bow cleats. The boat can free wheel about the mooring depending on the wind direction.

Tow Lines are used to tow a vessel behind a larger boat like a houseboat or yacht. Similarly, a Towing Hawser is a line used for towing purposes mostly used in heavy marine, commercial, and industrial applications.

Shore Lines are used to temporarily Moor (connect / fasten) or Make Fast a boat to the shoreline. These mooring lines can be long dock lines and or anchor lines often applied in house boating applications.

Storm Lines are an extra set of mooring lines brought out of storage when the weather gets rough and utilized to provide an additional safety margin (just in case).

Traveling Lines are an extra set of mooring lines used to provide flexibility for docking conditions when traveling from port to port as your normal dock lines might well be too customized for your slip arrangement back home.

Boat Fender Lines / Whips are smaller diameter lines used to hold your boat fenders in place against your boat’s haul. Boat fender lines are provided with a bitter on each end or with a small loop on one end.

Bitter End is the end of a line where no splices are provided. The bitter end is often seized (melted clean and whipped) to prevent fraying of the rope fibers.

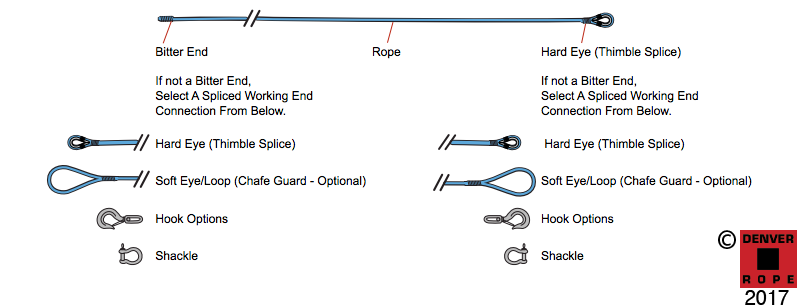

Eye Splice / Loop / Soft Eye Dock Lines and Mooring Lines are provided with a spliced loop on one end (even both ends), which provides for an easy method for making fast around a cleat, pile, bolted eye ring, etc. While the bitter end (free end) of the dock line is made fast to another cleat and the slack adjusted for tension (slack removed) using a cleat hitch.

Chafe Protection / Covered Eye Use Leather, Nylon Cordura Tubing, or Dipping to increase the life span of your lines as they rub against cleats, chocks, and your moorings. Chafe protection is most often used on eye splices, but can be used to protect other sections of the line below the throat of the eye splice (fairlead areas for example). Covered Eyes are a must for long term mooring applications. Is your boat moored in a slip? Then cover those eyes.

Thimble Splice / Hard Eye is a shapely grooved piece of metal (galvanized or stainless steel for example) which provides chafe protection against the connecting hardware like shackles, hooks, etc. The rope makes a tight bend around the thimble’s outside grooved channel and is spliced back into itself. The hardware will rub not on the rope, but on the inside smooth surface of the thimble. Anchor and Tow Lines most often have at least one thimble splice. Mooring Thimbles and Towing Thimbles are used in specialized heavy marine, commercial, and industrial applications (Hawser). Working Load is a fraction of the rope’s tensile / breaking strength used to provide a safety factor to account for splices, fiber wear, usage, knots, application, etc. Most often the fraction is at least 1:5, but can be larger depending on the application and fiber characteristics. Never exceed the safe working load of the rope / line.

Working Load Considerations For pleasure marine applications the working load is often chosen to be equal to the fully loaded weight of the towed vessel, but for larger vessels, ships, large yachts, barges, and heavy equipment this conservative approach is not practical and too expensive. For lighter duty applications, practicality, pleasure marine, lake applications, tow line storage concerns, and or budgetary considerations the W.L. is often chosen to be 1/2, 1/3, or some other fraction of the fully loaded weight of the towed vessel. We encourage the owner to consult with the manufacturer, naval architect, marine engineer, insurance company, and or other authorities of jurisdiction as to provide their recommendations and industry guidelines. The manufacturer may have to provide an engineered calculation (hydrodynamic ship modeling software) as to how much force is required to move / pull the vessel at slow speed for their specific vessel, ship, equipment. The WL of the towing assembly can be set to 2x the calculated force and the tensile strength set to 5x the WL. As opposed to calculating the force, a Static Bollard Pull Test can be performed to actually measure the pulling force.

Aft refers to the back end of the boat (toward the stern). Alongside refers to the side of the boat. Ballast refers to weight placed inside a boat to achieve the desired trim or draft.

Beam refers to the width (breadth) of a boat.

Bilge refers to the lower inner compartment of a boat’s hull. A bilge pump might be placed in this location.

Bitt refers to a post or bollard on a boat or dock area where mooring lines are secured to. There are single bits, double bitts, and horned bitts.

Capstan refers to a hand cranked or machine driven, vertical, spindle mounted drum that winds mooring lines and anchor rodes, which contrasts with a horizontal mounted machine called a windlass.

Bow refers to the front end of the boat.

Bridle refers to a V-shaped or Y-shaped line arrangement connected to the boat’s port and starboard cleats or bitts used during towing or mooring.

Buoy refers to a floating object used to identify a location (a navigation aid).

Cleat refers to a forged metal fitting with two project horns secured to a boat’s hull or dock area where a mooring line is made fast to (cleating a line using a cleat hitch). Kevel is another term for a cleat. Some cleats have a center hole or chock.

Chock refers to a forged metal fitting providing a location and guidance for mooring lines to pass though. Draft refers to the depth of a boat’s keel below the waterline.

Fairlead refers to an assembly of roller bearings facilitating the movement of a cable in any direction. A chock has similar functionality for rope applications.

Boat Fender refers to an object that absorbs and provides cushioning between a boat and the dock. Buoys can also provide this function.

Fish Plate / Towing Plate refers to forged triangular shaped plate with three holes that facilitates the ease of mechanical connection between a tow bridle and the tow line / hawser.

Freeboard refers to the distance between the waterline and the deck of a boat. Keel refers to the lowest structural member that runs the entire length of a boat along the centerline.

Hull refers to the main body of a boat that provides floatation.

Nautical Mile refers to a unit of measure equal to 6076 feet or 1852 meters or 1.15 statute miles.

Padeye refers to angular steel plate often affixed to the deck of a boat with a hole that provides for a mechanical connection for lines and or cables.

Shackle refers to a U-Shaped piece of metallic hardware with a threaded screw pin which provides for a mechanical connection between pieces of equipment like chain and an anchor.

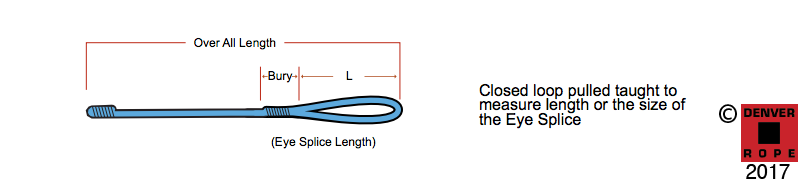

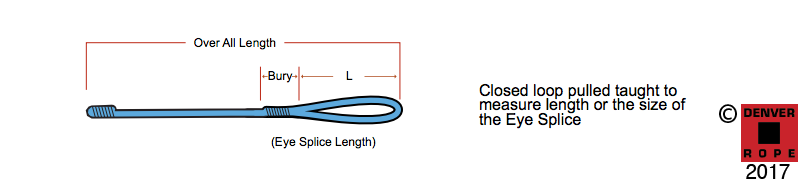

Measurements

Please consider the sketch of a dock line or any mooring line pulled taught as to measure the overall length (OAL) of the line Secondly, consider the sketch of the eye splice pulled taught as to measure the length / size of the closed loop “L”. The eye splice size / length is measured this way as to equal the one way length measured from the splice to the tip / far end / crease. The total length of rope required to make the eye splice would be 2 x L + bury of the splice, where the bury is often equal to 18 x the diameter of the line.

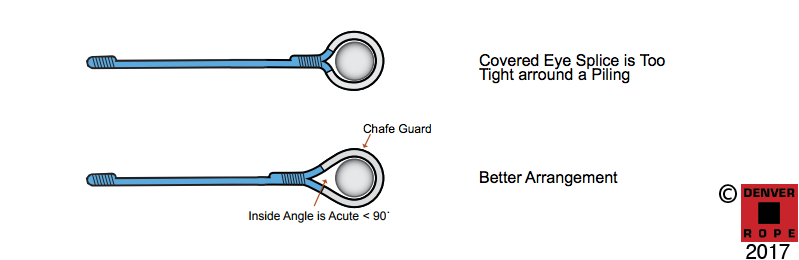

The amount of chafe guard to cover the eye splice would be 2 x L. Using geometry we can discover the relationship between the length of the splice and the perimeter of a circle; finally, the diameter “D” of a circle formed by the loop / splice where L = (11/7) x D. In reality one would choose a larger eye splice size as to comfortably slide over the piling and also not to overly stress the eye splice (keep the inside angle acute). Rule-of-Thumb L = 3 x D (min).

Dock Line Construction Diagram

Please consider the sketch of a dock line or any mooring line pulled taught as to measure the overall length (OAL) of the line Secondly, consider the sketch of the eye splice pulled taught as to measure the length / size of the closed loop “L”. The eye splice size / length is measured this way as to equal the one way length measured from the splice to the tip / far end / crease. The total length of rope required to make the eye splice would be 2 x L + bury of the splice, where the bury is often equal to 18 x the diameter of the line.

The amount of chafe guard to cover the eye splice would be 2 x L. Using geometry we can discover the relationship between the length of the splice and the perimeter of a circle; finally, the diameter “D” of a circle formed by the loop / splice where L = (11/7) x D. In reality one would choose a larger eye splice size as to comfortably slide over the piling and also not to overly stress the eye splice (keep the inside angle acute). Rule-of-Thumb L = 3 x D (min).

Dock Line Construction Diagram

Dock Line Eye Splice Around a Piling Diagrams

Mooring Line Diagram

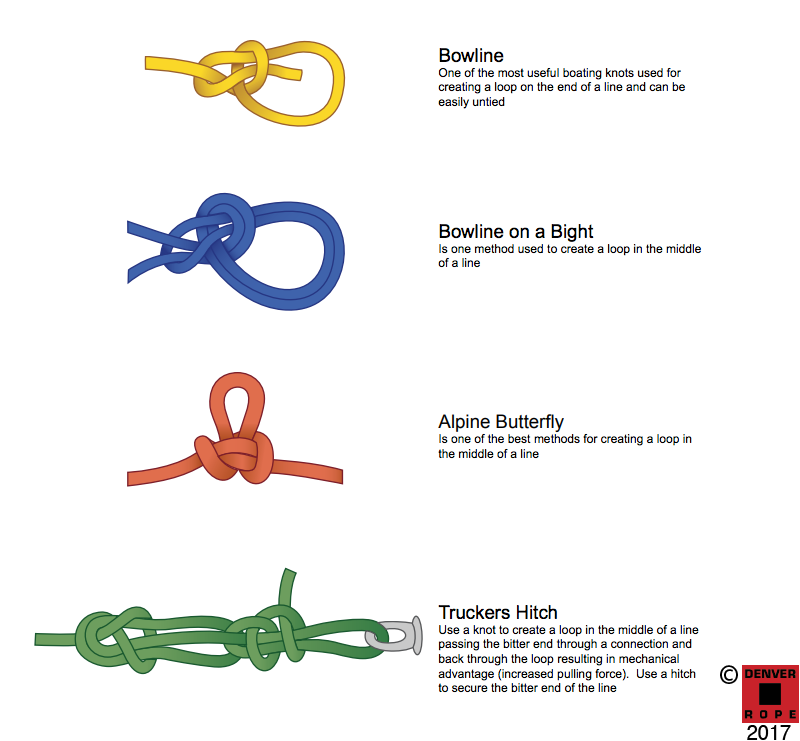

Knots and Applications

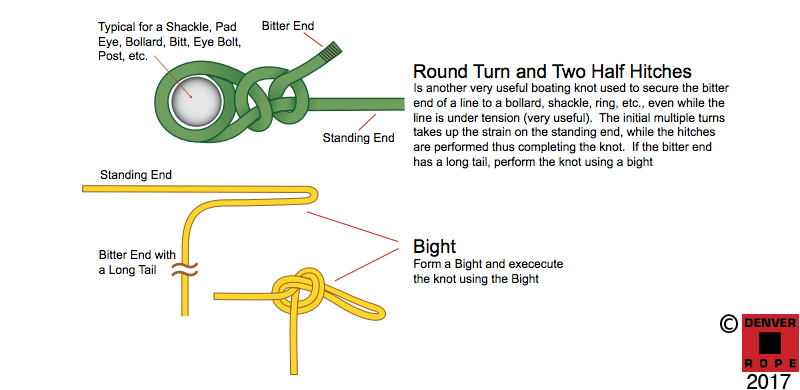

Standing End — The portion of the line that will be under tension.

Tail — The excessive portion of the line not to be under tension the very end of which is called the bitterend.

Bight — When executing / tying a knot and the tail is excessively long, one can overlap and squeeze the line together forming a bight; use the bight to finish the knot.

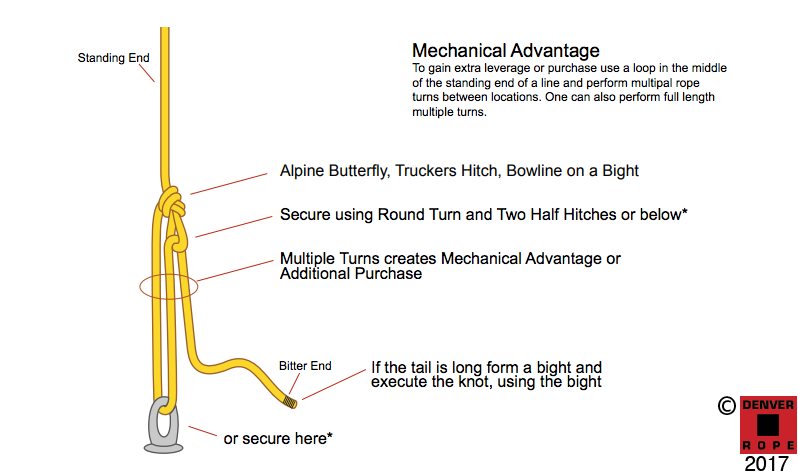

Mechanical Leverage / Additional Purchase — When performing a knot to secure a line from point A to point B, one can lengthen the distance of pull by adding multiple turns between the points (double, triple, etc) most often accomplished with pulleys and blocks, resulting in increased pulling force.

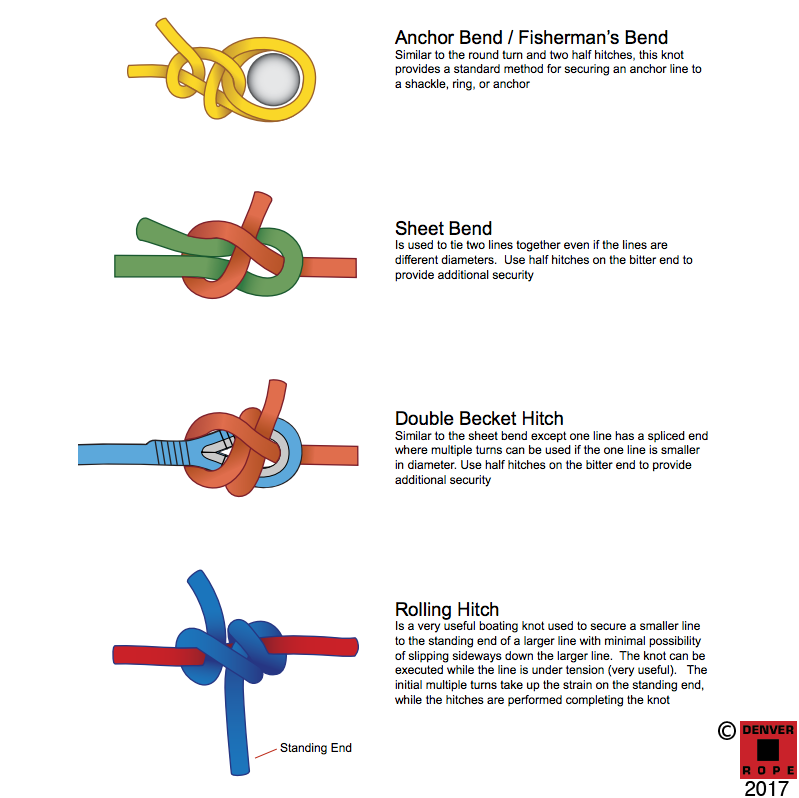

Please consider this useful animated website (www.animatedknots.com) for learning to tie the most useful knots for boating applications to include: bowline, round turn and two half hitches, cleat hitch, rolling hitch, anchor bend, sheet bend, and many others. Always practice making the knots required of your vessel before your boating trip.

Popular Marine Knot Diagrams

Houseboat Application

Houseboat Application Diagram